The Sentinel Rebreather

The Sentinel Rebreather Concept Description

|

The Sentinel Rebreather Concept Description |

|

||||

|

|

|||||

|

I decided to put this together based on comments and

observations at the last two dive shows.

Why did I design the Sentinel (S) and how does it differ from

the Ouroboros (OR).

The OR will always be our deep diving rebreather. It has very

low breathing resistance (resistive), great electronics and

manual backup systems and a virtually fail-safe gas plumbing

system (Swagelok 316 stainless). All of these things add cost

(especially the Swagelok!).

95% of divers will never take this rebreather anywhere near its'

performance limits.

My view is that recreational diving now regularly takes a lot of

people to 100m. This has led to the new design. Ten years ago

100m diving was heavy-duty expedition territory, now it is not.

100m as a bailout (with reasonable bottom times) is also not too

difficult logistically.

So the challenge is to make a rebreather more cost effectively

but still with an acceptable (and high) degree of performance.

Breathing Performance

Breathing performance should never be compromised in

life-support equipment and it is continually a balance between

low overall work of breathing and the size of the unit (in

particular the mouthpiece).

A unit that will always be used by very experienced divers, that

never get stressed, can arguably have a lower breathing

performance. A unit designed for a spectrum of the general

diving market must assume stress will occur and when it does, if

breathing performance is poor, the safety of the diver will be

compromised.

The energy expended by a diver to push gas around a rebreather

is a combination of three primary things.

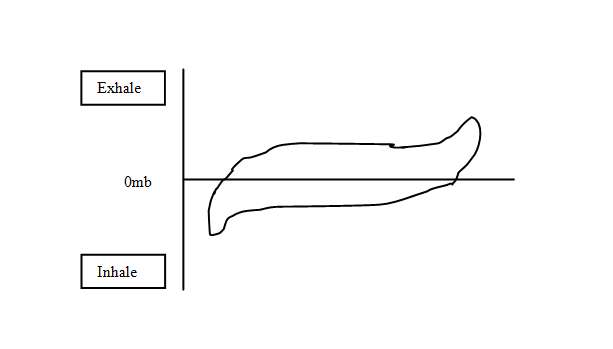

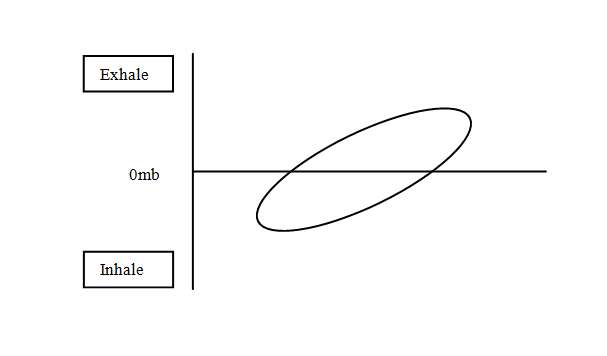

1. The resistance to flow of all the bores within the unit

(houses, mouthpiece etc.). At the surface as a diver breathes

out and in again a breathing performance analyser will show a

rise and then fall in pressure throughout the breathing cycle.

This is known as the Pressure/Volume diagram or PV diagram. At

the surface it is a sideways ellipse about zero pressure, much

like the shape of your eye. The area within this ellipse is

measured in Joules/liter and is known as the Resistive

Effort (RE) required to push gas around the breathing circuit.

At depth with increased gas density this ellipse will fatten,

increasing the Joules/liter. An increase in breathing rate also

increases the joules/liter. |

|||||

|

|

|||||

|

If the counterlung you are breathing into is too small for a

standard breath, the two ends of the ellipse will turn up and

down respectively. Further degrading the 'breathing feel' and

increasing the peak to peak pressure felt by the diver.

|

|||||

|

|

|||||

|

A low RE is essential in any rebreather design as the effects of

it cannot be compensated for by the diver, it is purely a

function of the mechanics of the rebreather.

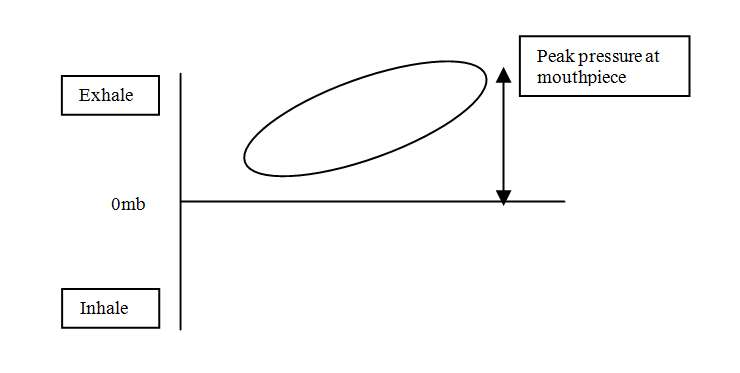

2. Once the unit is submerged, hydrostatic effect now plays a

part. Depending on the test position (vertical or horizontal),

the shape of the counterlungs (long/thin Vs doughnut etc.) and

their position in the set will affect the angle of the ellipse.

The ellipse, previously about zero, will tilt up to add a

minimum and maximum peak pressure to the PV ellipse. These peak

to peak pressures also affect 'breathing feel'. If the

Counterlungs (CL ) are long and this and the unit is anywhere

other than horizontal the PV will start to angle up

considerably, again degrading the 'b

reathing feel'. |

|||||

|

|

|||||

|

A CL of a safe minimum size (so as not to affect 1 above),

shaped around the centroid position of the divers lungs will

produce lower peak to peak pressures. Both this and the RE are

tested at depth with high ventilation rates, as again the diver

can do nothing to correct these issues in set design except

breathe slower.

Hence the results from 1 and 2 are additive and go towards

the total 'breathing feel' of the unit.

3. A final function is important and that is the Rotational

Hydrostatic Effect (HE). This simulates the diver moving into

different positions. It is function of 1 and 2 above and the

counterlung position (and shape) with reference to lung centroid

in these varying positions. It is currently conducted with a

fixed loop volume so that comparisons can be drawn. The rotation

has the effect of moving the angled PV diagram up and down about

the zero point (and in some cases modifying the angle) and in

effect creating an offset (addition/subtraction) in peak

pressure. |

|||||

|

|

|||||

|

So for the total 'breathing feel' of a set, 1,2 and 3 are all

added together at this stage. Test 3 gives the only result where

the diver has the ability to compensate for the pressures seen

at the mouthpiece as they can vent or inject manually in the

different positions or change position, thus improving the

'feel' somewhat.

Units with overshoulder counterlungs generally have a lower HE.

But if counterlung volumes are excessive or are not constrained,

the HE results can be compromised significantly.

Backmounted counterlungs traditionally show high HE when the

diver is swimming on their back.

So given that the total breathing feel of a set is a function of

all three of the above, almost any CL concept can be made to

generate a good overall work of breathing. Well designed

over-shoulder counterlungs traditionally solve the HE problem

quite well but designs often compromise items 1 and 2 as a

result, which remain un-adjustable by the diver.

Over-shoulder CL's have their own issues such as 'harness

clutter' and large buoyancy shifts, which can in-turn affect the

sets ability to track PO2 setpoint accurately. |

|||||

|

Absorbent Filters

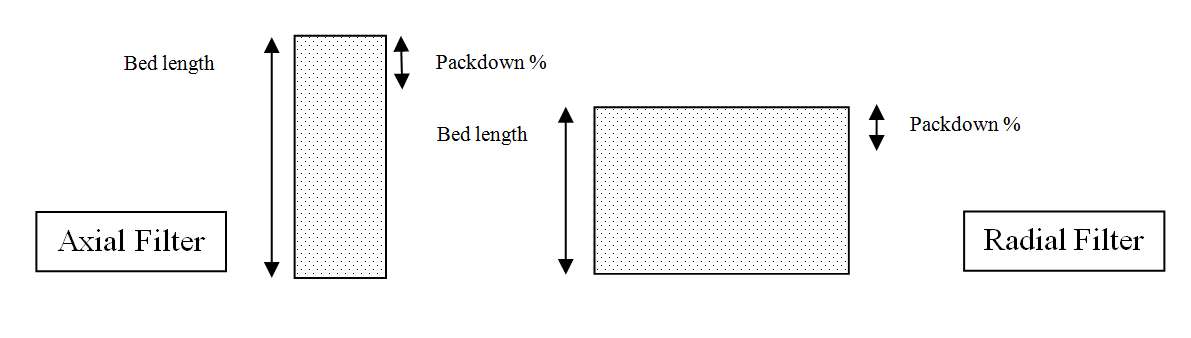

Traditionally we have been led to believe that axial designs are

a low-duration performer and radial is high. This is not always

the case. What can be said is that radial designs have a lower

breathing resistance due to the bed length and are often less

prone to packing errors due to the bed height versus the pack

down % (at least in doughnut radials). |

|||||

|

|||||

|

Axial canisters can be just as efficient.

The Sentinel can uses a granular (Sofnolime 797) user packed

absorbent system. This interfaces to three absorbent monitoring

systems (later).

Counterlung

The unit comes as standard with one back-mounted counterlung

(CL). This CL is teed off of the inhale side of the loop at the

output of the canister head, hence the inhale breathing hose is

not actually connected to it, it is just provides an expandable

volume. In a head-down position water will preferentially drain

into the CL. When the diver goes head-up again, water drains

back to the canister base where the water/gas dump is

positioned.

The single back-mounted CL has several advantages;

1. More protection

2. Less heat loss

3. Simpler flood recovery

4. Reduction of failure points

A second option is now available for the Sentinel, the Travel

Kit. The set will be available without its' hard case. A range

of cylinders sizes can attach to a fold-flat back plate. To this

you can attach and BC/Harness.

This configuration will allow the diver to travel with a

small/lighter set. |

|||||

|

Gas systems

The set has no high-pressure (HP) hoses. It uses digital HP

sensors fitted directly into the first stage. The digital

HP provides content and usage/leak alarms.

The set uses the same oxygen solenoid as the Ouroboros. It is

rated to over 15 bar as an interstage pressure. The regulator

first stages can be either Poseidon or Apeks with a 12 bar

(approx.) over pressure valve (OPV), primarily to protect the

solenoid and low pressure (LP) piping.

The LP circuit does not use conventional hoses. It uses

super-flexible LP tubing with a woven protective cover with a

burst pressure of 200 bar. The tubing is more resilient to UV

and saltwater in long-term use than rubber. It is also lighter

and more flexible.

The Expedition version of the sentinel comes with an off-board

gas connector (Swagelok) fitted to each block. This system is

unique in that it not only allows off-board gas to be injected

manually but it also routes it through the automation (ADV,

solenoid). The diluent off-board is even available at the

Bailout Valve (BOV).

The BOV is integrated into the mouthpiece (which is neutral

in-water). Simply rotating the switch selects open or closed

circuit. |

|||||

|

The BOV is used as a 'sanity' breath system. This is especially

useful in hypercapnic incidents where there is a strong desire

NOT to switch off the set to an alternative bailout regulator.

The 'sanity breath' allows you to asses the situation and then

take the correct action.

The BOV and breathing hoses are counterweighted to offset

buoyancy.

The breathing hoses are fitted to the canister head via a dual

lock quick-release system, compromising a quarter-turn and a

push button. The hose ends are double radial O-ring sealed. The

complete mouthpiece and hose assembly can be quickly removed for

cleaning as can the CL.

The diluent LP circuit is fed from the first stage through a

multi-port manifold to allow connection of BCD/suit feeds etc.

The HP sensors use a 'dynamic reserve' system. On the diluent

side, dependant on depth and an assumption of open-circuit

breathing rate, the reserve alarm will vary. Hence in shallow

water the alarm will trigger later compared to deep water, still

allowing a safe ascent to the surface.

Oxygen setpoint control is also dynamic. The set can be put in

'auto-setpoint' mode. PO2ís for bottom-mix and decompression-mix

are adjustable over a range.

Upon submersion the unit will slowly increase the setpoint to

the preset during the descent. Once at a stable depth the diver

can select the high setpoint themselves or wait until the set

automatically switches.

Upon ascent the set will remain at the high setpoint until the

safety or required decompression is complete and then decrement

towards the surface (reducing to 0.7) to avoid unnecessary

buoyancy shifts.

The loop over-pressure valve is located in the canister base. It

is also the water drain. It is unique in that it can be set on

the surface for a given pressure and then irrespective of the

position of the diver in the water, it will always dump at

approximately the same pressure.

The set comes with dual 2l cylinders. As the base foot of the

case is extendable (or removable) longer cylinders of a similar

diameter can be fitted. As the 1st stages are free to move,

almost any style of cylinder valve can be fitted. The standard

valve supplied is an AP Diving cylinder valve. |

|||||

|

Electronics

The unit comes with electronics similar to the Ouroboros with a

different human-computer interface (HCI).

There are two HUD's, one front and one rear. A Primary display

and a Backup display.

All the electronics, solenoid and batteries are outside of the

breathing loop.

The Primary display connects to the Core Life-Support Module in

the canister head via a cable. The Primary does not contain any

system control electronics and is just a display. The Core

Module provides life-support and decompression status.

The HUD's, Backup display and HP sensors also connect into the

Core Module.

Electronic failure of any display will not affect life-support

functionality.

The HUD on a level one unit has 3 states.

Green - All OK

Amber - Your consumables are running low, slowly ascend towards

the surface on closed circuit (often this alarm will go away on

ascent.

Red - Perform open circuit bailout now. You will then be

prompted to switch the Primary to open circuit decompression.

The HUD on a level 2 & 3 follows the Ouroboros logic and gives

additional information on decompression, PO2, solenoid status

and general alarms.

All HUD's have visual and tactile alarms. The tactile alarm only

sounds at extreme alarm levels to reduce 'alarm blindness'.

To activate the unit the user can do so in three ways.

1. By switch on the Primary (the pre-dive sequence check-list

will then automatically start)

2. By entering the water and getting to depth (1.3m approx.). A

pre-dive abort alarm sound and be logged.

3. By breathing the unit on land or in the water. This final

'auto-breathe' function is the primary fail-safe. The unit will

turn on when it senses breathing and provide a minimum

life-support (irrespective of setpoint) of 0.4 PO2.

The Primary and Backup come with a colour screen. The VGM

decompression algorithm is available as an option. |

|||||

|

Pre-Dive Check-list

The unit has a pre-dive check-list on-screen which is activated

at every power up. While (in an emergency) it is possible to

abort the check-list and start diving. A Pre-dive abort alarm

will sound for a period and the abort will be logged in the dive

log.

The pre-dive sequence is intelligent in that it knows when the

filter has been removed (hence the unit has been apart) and how

long it has been at the surface between dives and will adjust

its' pre-dive sequence accordingly, prompting for more or less

checks. |

|||||

|

Oxygen Sensor Calibration and Filter in/out Detector

The set has oxygen sensor logging (alarming when it is time for

a change-out), Voting logic with manual override and the ability

to calibrate the cells during a filter change when exposed to

air.

A removal and replacement of a sensor will force an automatic

air calibration of the oxygen cells in the background. Exposure

to ambient air must be ensured during this procedure and

altitude calibration is automatic.

Calibrating on air is applicable given sensor failure modes and

sensor characteristic modelling.

Primary power is supplied via triple-redundant Lithium-Ion

rechargeable batteries. The backup display has its' own

battery, charged with the main system.

Chargers are available for a range of AC and DC voltage sources

(mains/car etc.) as well as emergency charge capability via a

stand-alone plug in charger pack with its' own batteries.

Canister Duration Monitoring (CDM)

The CDM is under license from the United States Navy, who have

completed hundreds of research dives to correlate the thermal

wave-front within a filter and compare it with when a given

millibar of CO2 breaks through the filter. Further enhancements

have been completed by VR Technology to show filter duration

remaining as a bar graph in 5% increments. The CDM can work with

all three filter mediums by simply selecting the correct filter

during the pre-dive sequence.

Backup oxygen metabolism predictor software provides additional

fail-safes which operate in parallel with the CDM.

Expedition units also have a gaseous CO2 detection system.

Data-logging

All sets are configured with full 'black box' data logging

capability of all key parameters. An optional PC link system is

available.

Maintenance

The set logs usage hours and will prompt for factory service. It

is possible to strip the complete breathing loop down to its

component parts without any tools.

As the hoses and counterlung are quickly removable hence

cleaning routines are simplified.

Basic field maintenance right through to completely taking apart

the mouthpiece, is all tool-free. |

|||||