|

IDA-72

SCR Conversion to MCCR

project Conversion done by Johan Pretorius |

|

|

1st things 1st and thanks, honours and credits

to those that deserve it. |

|

|

I got most of my inspiration and all my theoretical knowledge on the

IDA-72 from Dave’s “nobubble” site, the work he did for other IDA-72

divers and for that I must thank him.

A lot of the modification ideas were bounced of my good friend and

dive buddy

My father who assisted me in the modification process, although not

a diver himself, his simple logic, insistent questioning of my

thinking and reasoning, as well as his ability to do magic with

limited tools, helped me resolve many of the issues I got stuck

with. |

|

|

This is my documented effort to convert a Russian manufactured Deep

Water Umbilical Supplied Heliox SCR (Semi Closed System rebreather)

named the IDA-72 to a

MCCR (Manually Operated Closed Circuit Rebreather) with

Trimix capabilities. I tried to keep the system as original as

possible, so as not to lose the essential character of the machine,

although the machine’s working character had to be completely

changed for the process to be successful. (If that mumble makes

sense to anybody?) The main reason why I chose the

IDA-72 as my rebreather of choice is very

neatly summed up in the following paragraph, taken from Dave

Sutton’s website. |

|

|

“The Russian IDA-72 is a rather unique Semi-Closed Circuit

rebreather designed to be fed by an umbilical for surface-supplied

or saturation diving using Heliox. It has 2

x 2-liter internal cylinders that were originally designed to be

used as bailout cylinders in case the umbilical supply was lost, a

very large scrubber capacity, and an extremely interesting belt-worn

valve block that allows the diver to flush the loop and also to

split the loop and cause the rig to become a demand-only system.

This last feature is totally unique as far as I can determine, and

is a very interesting design feature. This feature alone makes the

IDA-72 worthy of close study.”

- Dave Sutton |

|

|

|

|

This meant that with some clever modification, I can have a Closed

Circuit Machine, designed to work at 200m depth, with a belt block

that allows me to effortlessly flush the loop with dilluent, and the

ability to switch to an Open Circuit demand system, with the flick

of a switch. |

|

|

I am not going to give a tear down of the machine in stock standard

format, as this info is already excellently documented by Dave

Sutton, and the info can be viewed on his website at the following

address:

http://nobubblediving.com/old_site/ida72.htm |

|

|

A quick visit there will acquaint you with the workings of the

original stock standard IDA-72 and can help understand how and why

certain systems work.

The machine will offer the following inherent and added safety

features when completed:

Here you have what I believe, is the safest Rebreather system

available (not on the market today).

Works for me……. |

|

|

Stripping the machine

Not a very nice time for me….Having to remove the heart, or is it

guts, of the machine?…

But, all parts were safely kept, with as little as possible damage

done. I tried to keep the machine as original as possible, but some

stuff had to go….

What I ended up, is basically a bare chassis, with a breathing

plenum and what I call the dilluent injection array consisting of an

inlet connector with OPV and two pipes that will feed the breathing

plenum and allow for operation mode switching.

But, I had the basis of my MCCR rebuilding plan.

The huge chassis of the machine lends it self to various

opportunities and possibilities, and I had to really keep focus on

hat I wanted to achieve. Don’t be fooled, the scrubber that goes

into the cavernous chassis is HUGE. |

|

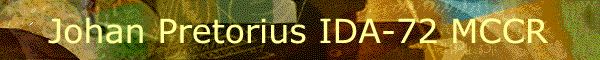

|

|

|

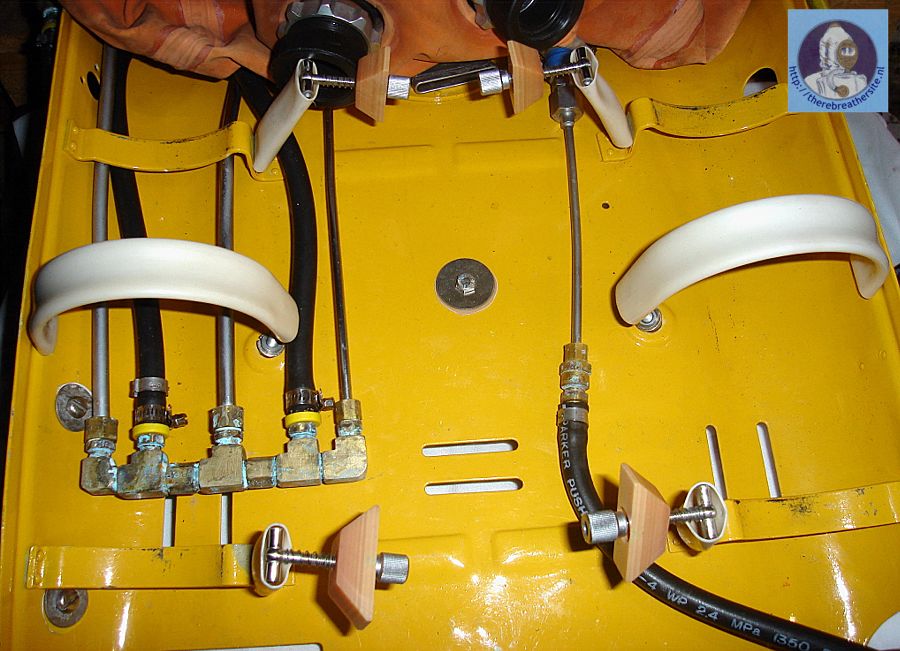

The breathing plenum on the left, with the two pipes that will be

supplying pressurised gas for mode switching. The original cylinder

belts are still in place and will be used as is. The snakes’ nest

that is supposed to be found at the bottom has been removed, as it

will unfortunately not form part of my conversion idea.

|

|

|

|

|

Diluent injector array and gas plumbing

The IDA-72 is very cleverly designed. It was designed to be fed by

an umbilical from a diving bell or similar type of set-up at extreme

depths. This meant that the IDA-72 had a very smart dilluent

connection system, to ensure the dilluent got to all the important

places. I decided to keep the system as unchanged as possible

(mostly). Unfortunately I had to remove the female umbilical

connector as the male part is in

I opted to put in a Quick Connect system, with the female Quick

Connect on the Dilluent supply and the male Quick Connect on the

rebreather. The Umbilical connection has an “interesting” thread

size, and I had to source an adapter to fit the connector, which

ends in a ¼ inch push lock barb. An alternative would be to drill

and tap the female connector, so that a ¼ inch barbed fitting screws

into the machine. Not having a ready available means of doing this

work, I opted for the adapter which meant that I could use off the

shelf parts.

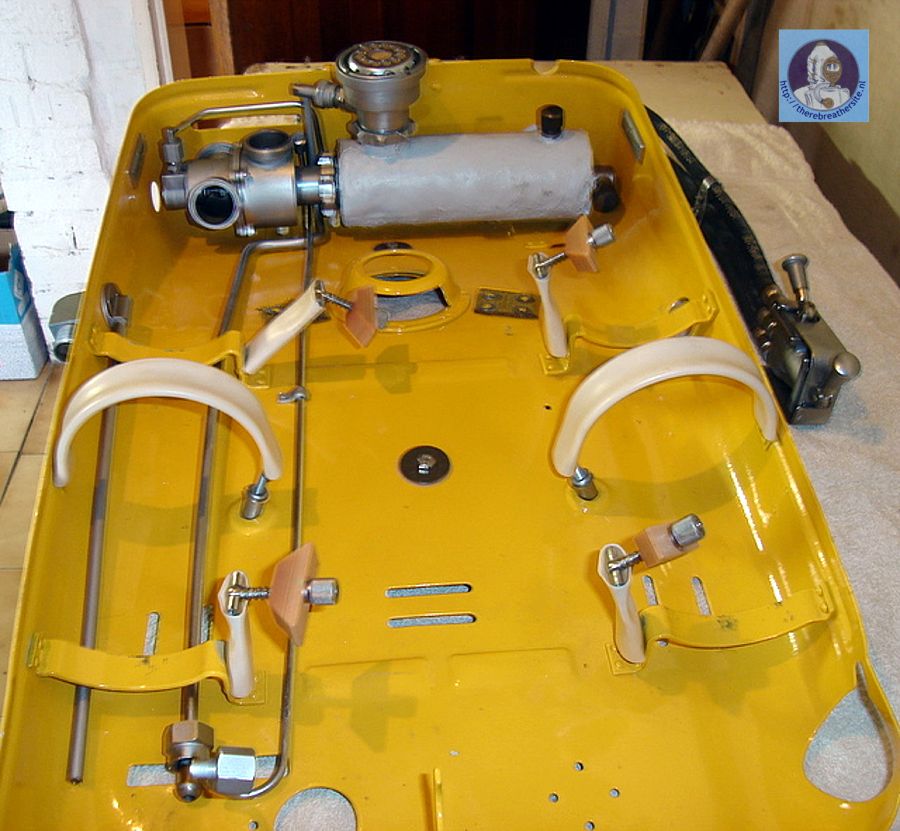

Due to the possibility of using off board dry suit inflation, I

needed to move the dilluent connector as high up the rebreathers as

I could. The dilluent connector has its own proprietary overpressure

valve that protects the system against over pressurisation. |

|

|

|

|

The parts of the Dilluent connector adapter |

|

|

|

|

|

|

I used silver solder to permanently fix the parts of the dilluent

injector adapter, so as to minimise possible failure points |

|

|

|

|

The dilluent connector adapter polished and installed. Note the

proprietary over pressure valve |

|

|

|

|

The Quick connect and ¼ inch hose installed. Note the Ferrules used

to clamp the hoses additionally to the gripping power of the

Pushlock barbed system. A bolt snap on the male QC is to secure the

QC when not connected to the Dilluent supply. The original position

of the dilluent injector can be seen to the left of the current one

Important to keep in mind, is that the dilluent not only serves an

important purpose on the breathing gas side of things, but also

drives the important features of the machine. I had to route the gas

supply from the dilluent connector to all the important parts in the

rebreathers. To be able to do that, I needed to build a manifold

that could withstand 11 bar interstage pressure, with enough outlets

to ensure that all the parts that need gas, can receive it.

Below is a picture of the dilluent manifold, with a numbered

sequence. The numbers are for explanation of what each pipe does. |

|

|

|

|

|

|

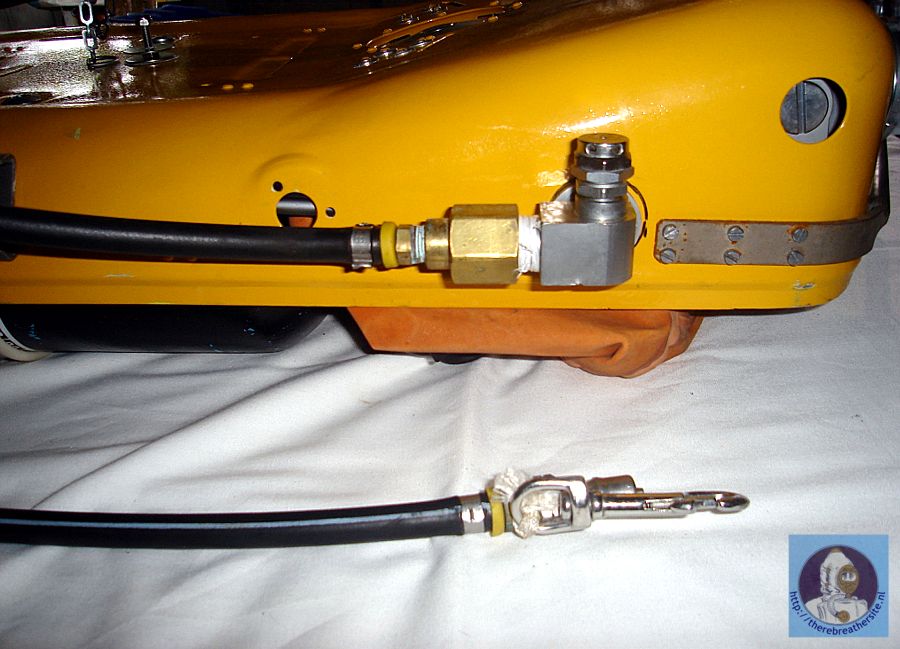

The Oxygen supply and routing

The IDA-72 originally has two x 2L onboard Trimix cylinders rated at

200 BAR. These cylinders are ideal for use as the IDA-72’s onboard

Oxygen supply, (and therefore the colour change, black & white is

the legal colouring for Oxygen). To effectively use the smaller

cylinders in conjunction with the large scrubber, I opted to have a

manifold manufactured to connect the two internal cylinders. The

manifold then allows a capped DS4 to be connected. This gives me a

few options for future use.

I noted that Copper Oxide (the green stuff you see on copper and

brass fittings), may become a problem in future. The alternative is

to have the brass and copper parts chromed. That will be the final

step in the completion of the system |

|

|

|

|

Close-up of the IDA-72 BIG scrubber in place with the Oxygen

manifold and DS4 1st stage |

|

|

|

|

Close-up view of the Oxygen manifold and capped DS4 The blue

scrubber is a IDA-71 scrubber with a slight modification |

|

|

|

|

The Oxygen manifold and installed DS4 1st stage is

clearly visible, with the CMF on the right hand side of the table.

The male QC for the dilluent supply is visible on the left hand side

of the SPG |

|

|

|

|

Close up of the gas supply system. On the left is the Dilluent

manifold, Bottom is the DS4 and the

Hydrogom CMF valve. The hose on the right is

the Oxygen addition to the counter lung from the Hydrogom valve. ;

note the copper oxide already forming on some brass parts. Chroming

of the parts may be a solution |

|

|

|

|

PPO2 Monitoring

The mantra of all Rebreather divers.. “Always know your PPO2”

Although the MCCR IDA-72 uses a CMF (Constant mass flow Valve) to

bleed Oxygen into the loop, it is still vital to be able to monitor

the PPO2 in the system, so that the diver can make the necessary

adjustments to the gas he/she is breathing.

A rebreather is in effect a Nitrox / Trimix factory carried on the

divers back. Using the same tried and tested method used in the

conversion of the “Franken-son” and relatives; I opted for

installing a P-connector system and independent PPO2 monitoring.

The question has always been how many PPO2 displays do you really

need?

I opted for a very simple solution to this perceived “problem”

I installed only two independent PPO2 displays, and my diving

philosophy is simple. If at any stage during the dive, both PPO2

monitors do not give me the same reading, I bail out and do an

ascent on bail out gas, which I carry in an AL-80 cylinder as a

sling / stage cylinder. No discussions, no loop flushes, No funny

stuff. It is just not worth it. – rather come back tomorrow. If my

dive buddy has a problem with that, I will find a new dive buddy.

Two independent R22D Oxygen cells do the monitoring and the displays

are read from two independent monitors.

I am utilising one home built PPO2 display, that a friend of mine

makes, and the second is my VR3 dive computer that doubles as PPO2

verifier and deco calculator. To solve the problem of two cables

coming out of the machine, and lying everywhere except where they

should, the cables are fed through 25mm tubular webbing, which

protects the cable and helps with clean neat routing. |

|

|

|

|

The two Drager female P-connectors installed in the counter lung.

The Oxygen inlet can be seen protruding just under the right Counter

Lung attachment |

|

|

|

|

Two independent PPO2 monitors (VR3 & home built) |

|

|

|

|

PPO2 monitoring installed. Tubular webbing can be seen ensuring neat

routing and protection of the monitor cables |

|

|

Scrubber Modification

The IDA-72 has a HUGE scrubber. It must be seen to be believed. It

holds approximately 5 Kg of sorb, with dimensions that are about as

big as a shoe box. The 5 Kg of sorb should be equal to about 5+

hours of continuous diving in our cold Atlantic water, although your

mileage may vary.

This is a complete overkill for most sport diving, but the unit was

originally not designed for sport diving. It was designed to handle

the gas volume at 200m which is equal to 21 BAR absolute pressure,

when the diver engages the Trimix bail out option.

This meant that using the BIG scrubber exclusively, would result in

a waste of sorb, as I am not a great fan of re-using and leaving the

same sorb in the scrubber for too long, as it is cheap enough to

warrant often change (well.. cheaper than a life, definitely !)

The IDA-71 has a very efficient scrubber canister, which holds

approximately 2.1 Kg of sorb, which is more than adequate for a

weekends’ rebreather diving to depths less than 30m.

I decided to have an adapter made up, to allow me to use the IDA-71

scrubber with the IDA-71. A straight forward fit is not possible, as

the scrubber connection hoses of the IDA-72 are of a much larger

bore than the IDA-71, even though they have the same type thread.

The adapters were turned up from Delrin which screws down on to the

IDA-71 scrubber, and fits the IDA-72 scrubber connector hoses.

This allows me to use a smaller and lighter IDA-71 scrubber for

normal shallow water diving, but still allowing the full use of the

machine’s BIG scrubber for serious deep or long dives, should I

choose to use it. |

|

|

|

|

IDA-71 scrubber with adapter to fit IDA-72 scrubber connector hoses |

|

|

|

|

Close up of IDA-71 scrubber with adapter to fit IDA-72 scrubber

connector hoses |

|

|

|

|

Scrubber connector’s fitted to the IDA-72 counter Lung |

|

|

|

|

IDA-71 scrubber fitted into IDA-72 chassis with scrubber adapters in

place |

|

|

|

|

IDA-72 with Oxygen manifold, DS4 and BIG scrubber in place. Gives an

idea of size of the scrubber |

|

|

Breathing hoses

The IDA-72 has an interesting proprietary hose system. It consists

of a huge outer hose that serves as a warm water jacket for the

breathing hoses within. The purpose was to warm the divers gas (Heliox)

for breathing purposes. This system is totally unsuited for sport

diving, and had to be changed, unfortunately.

The inner breathing hoses are spiral hoses that are quite stiff and

may be difficult to dive with, if not connected to a helmet of some

sorts. At a later stage I will be connecting my Drager Panorama Full

Face Mask to the IDA-72 and the hoses might be used.

For my current diving needs, I opted to use Drager Ray hoses as they

are easily found and a pleasure to dive with.

The inner diameter of the Drager hoses is also a 100% fit over the

proprietary breathing hose connectors that come with the IDA-72.

I used jubilee clamps (Stainless Steel hose clamps) and tubular

webbing to secure the connectors to the hoses |

|

|

|

|

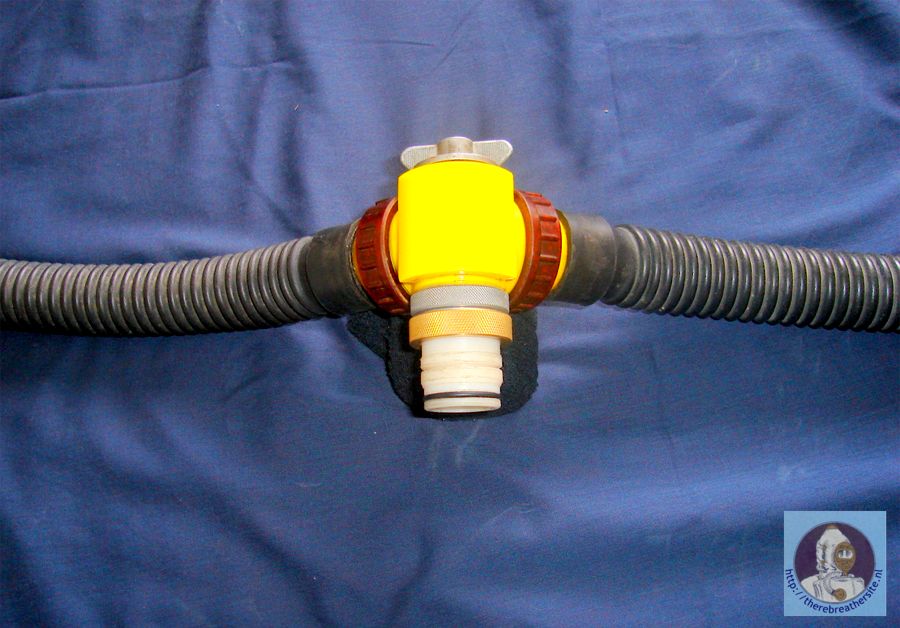

The Drager Ray breathing hoses with the yellow IDA-72 hose

connectors |

|

|

|

|

Up close of the hose and hose connectors. Note the SS hose clamp and

tubular webbing |

|

|

Drysuit inflation system

Due to our cold water, and taking into consideration the types of

dives that are being planned with this machine once it is completed,

a separate drysuit inflation system will be needed. It would have

been easy to add an additional hose from the manifold, or tee-off

the wing LP hose to include a dry suit inflation hose (another idea

) but due to the fact that Trimix can and will be used in the

machine, it is not such a great idea after all, as Trimix is not

known for it’s insulation properties.

This means that an independent system must be put in place.

The system consists of a set of “G” clamps and my IDA-71’s 1L Oxygen

cylinder and a Drager Kleinkonisch pillar valve.

The female “G” clamp is secured to the IDA-72’s chassis with

recessed machine screws and nuts. Care was taken to ensure that all

the dissimilar metals were “insulated” so as to prevent dissimilar

metal corrosion. The IDA-71 cylinder neatly slides into the female

“G” clamp and a Drager Kleinkonisch pillar valve does the rest.

The cylinder colour (light blue) is close enough to our legal

colouring for Argon, which is referred to as Peacock Blue.

The cylinder sits on the left hip, behind the wing and will be

filled with either Argon, or Air and will have its own 1st

stage regulator. |

|

|

|

|

IDA-71 Oxygen cylinder with male “G” clamp |

|

|

|

|

Female “G” clamp on the left side of the chassis. Note the blue PVC

inserted and neatly trimmed following the edges between the “G”

clamp and the IDA-s body, to prevent dissimilar metal corrosion |

|

|

|

|

The drysuit inflation cylinder installed, ready to go, just add 1st

stage |

|

|

Wing and harness

The IDA-72, like the IDA-71, is contoured to fit the divers back

profile. It is therefore very difficult to attach a stainless steel

backplate to the IDA-72.

The proprietary harness that came with the IDA-72 is incomplete,

which I believe it to be the case, rendering it basically useless

for our use. So it had to go…

By inserting strategically placed 6mm stainless steel bolts, an

Oxycheg “O” pack can be bolted securely to the back of the IDA-72.

The “O” pack is a soft, but very strong nylon backplate that is

perfectly suited for the purpose.

The wing is a 50Lbs (22 Kg) lift double tank wing that provides more

than adequate lift for the machine during a dive.

The harness is in the Hogarthian gear configuration, leaving ample

place to attach bailout cylinders, dive lights etc |

|

|

|

|

Harness webbing and soft “O” pack |

|

|

|

|

6mm Stainless Steel bolts and nuts to secure the webbing harness,

once again all dissimilar metals have been “insulated” |

|

|

Bail out regulator / Full Face Mask

Currently the Machine has a bungeed bail out regulator, which is fed

from the Dilluent manifold. It is not the ideal solution, but as

with most works in progress, it is a start. It is important to

realise the shortcomings of the system, although the ability to

switch to OC mode is a great asset, inherent to the machines

original design.

I plan to do all my rebreather diving with a FFM, and to be able to

use the FFM, the following modifications have been done.

The IDA-72 DSV is a very nice designed piece of equipment but it is

definitely designed to fit onto a helmet of sorts.

I decided to use a FFM with the IDA-72, and possibly utilising the

proprietary DSV and spiral hoses, if the hoses prove to be

comfortable to dive with. Doing this would serve the purpose of

adding more of the original flavour to the diving machine, without

increasing the conversion costs.

|

|

|

|

|

IDA-72 DSV view from the front. The metal ring can be seen, with

thread, meaning that a connector from a diving helmet must have

screwed onto the DSV |

|

|

|

|

IDA-72 DSV viewed from behind. Note the big turning

knob. |

|

| (DSV = Diver Surface Valve) | |

|

The movement of the DSV is fluid and is a half turn to either side

for open or closed positions. Unlike the Dräger DSV, there is a

large “hooded” vent on the top of the DSV. Opening the installed DSV

to surface air, makes breathing thought the FFM and installed DSV

very easy.

The DSV was definitely not designed to be removed from the helmet

during diving, as you would do with a normal DSV in case of a bail

out scenario. That would explain the need for an OC bail out

function, such as provided by the Belt switch Block.

So does form follow need or

visa versa?

As the machine did not come with a helmet (probably stored on the

same Nuclear submarine of sorts as the male Umbilical connector) I

had to turn to invention, to solve the problem of making all the

parts fit.

An engineering company who are always eager to help us divers with

our little projects turned a DSV-P-Port connector and a locator ring

based on my description. |

|

|

|

|

The prototype DSV – to - P-port connector and locator ring |

|

|

|

|

The DSV – P Port connector installed in the IDA-72 DSV ready to be

mounted in the Drager FFM

Not having a ready supply of Drager Shark regulators,

or a convenient C&C milling machine, I had to come up with an idea

of how to convert a normal SCUBA 2nd stage DV to a DV that will be

able to connect to the Drager Panorama FFM.

I had shortened male Drager P-port adapters turned from

Delrin (Acetal) that would serve the connecting purposes.

|

|

|

|

|

Turned up shortened Dräger

male P-port connector

The P-port connectors were mated to a normal SCUBA DV with the use

of a file and some “Pratley

Putty”, which are two chemicals, in the form of pliable “play

dough” sticks, that once combined in equal quantities, after 10

minutes or so, becomes rock hard and NEVER lets go.

The file was used to take the edges of the oval connector where the

SCUBA bite piece is cable tied on. This resulted in a 100% fit

around the sides, as the round P-connector is fitted over the SCUBA

DV mouth piece.

The Pratley Putty sealed the flat sides of the oval mouth piece and

is responsible for holding the system in place.

I tried to dislodge it, but found it cannot be done, not without

some serious use of excessive power and maybe tools |

|

|

|

|

The P-port installed on the SCUBA DV |

|

|

|

|

Close up of the inhalation side of the DV. The Pratley steel can be

see around the oval opening, keeping the system together |

|

|

All that is left is to install all the

elements and bring the system together. |

|

|

|

|

The DSV installed on the

Dräger

Panorama FFM |

|

|

|

|

I would like to thank Johan Pretorius for sharing his project with

us! If you have any questions don't hesitate to contact me |

|

| published 01-12-2008 | |

|

More Sources: |

|

| Please sign my Guestbook | |

| Email: jw.bech@quicknet.nl | |

Johan Pretorius rebuild the Russian IDA-72 to a manual operated closed circuit rebreather. He modified the scrubber system in such way the rebreather can be used for both short and long dives. He also changed the loop to fit a full face mask. Here you find his detailed description

Mainmenu:

Search this Website

Information about RB

Photo galleries

Historical Information

Links & Downloads

Reviews

Homebuilders

Electronics

Updates, speed menu

Web shop

Reviews SC rebreathers

Reviews CC rebreathers

RB’s through the ages

Inspiration rebreather

Database Oxygen RB’s

Database Semiclosed RB’s

Updates

Speed menu

Search this web