|

Second Generation rebreather MeCCRV2 |

|

General definitions

We in Switzerland are often diving in cold

water. The RB must be of certain robustness. Not to heavy, see water

resistant. Cleaning must be easy, refilling fast. Two dives without

service are nice.

That defines 5 liters of diluent, 1.5 liter

for the dive, 3.5 for safety, 200 bar is enough, as you can get it

anywhere. Retrofit for second diluent gas is foreseen. 2 liter of

oxygen is enough. 2 Kg of chalk is also enough.

O2 injection is adjustable, constant mass

flow with possibility to retrofit additional O2 injection by a

digital electronic valve. Diluent and O2 hand valves give full

manual control of the mix.

The lungs volumes are inside the box and

adjustable 4 – 6 liters.

Jacket is constantly fixed in form of a

wing; plus lead pockets. No lead weight is fix mounted, all are easy

to take away for transportation.

O2 Sensors are on ambient pressure; rest of

all electronic is on constant 1 bar. One O2 gauge is fixed part of

the RB with very long battery lifetime; big lighted numbers are a

must in my age.

A battery for the light should be inside

the housing.

Details

On my first dive with a RB, my scrubber was

flooded after 5 minutes.

One old sentence says: Never touch a

running system. So my rebreather must be constructed to stay

normally assembled, included cleaning, beside the only exception of

taking away the breathing tube after dive. Also exchanging the chalk

must be done with minimal removing. |

|

|

Points of concentration:

a.)

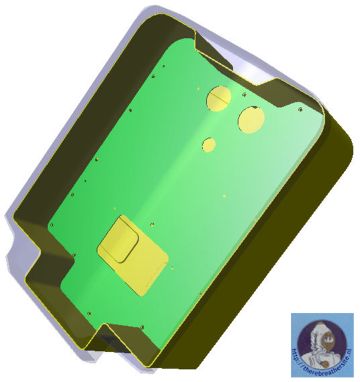

All connections on a fixed body |

|

|

|

|

b) Lungs. I wanted them flat on my body. That defined the basic positioning of the components. The way I positioned the two lungs can “store” a lot of water before I might have a caustic gasp. On my first RB I used the Dolphin idea and installed those plastic screws. Nice but fiddling around with cold fingers was nerving. To clean them easy they end in a triangle and in the corners small tubes are glued in. These tubes end at the bottom of my RB and are closed by small Garden water valves. As the lungs are between the RB body and a mounting plate the volume is defined. I planed to make the volume easily adjustable by placing on top an additional plate between mounting plate an lungs. By using some screwing system I could have restricted the lungs volume by increasing distance between mounting plate and this plate, but this pressing together of the lungs was not necessary. Maybe in next RB… |

|

|

c.)

Housing and pneumatic and weight considerations. |

|

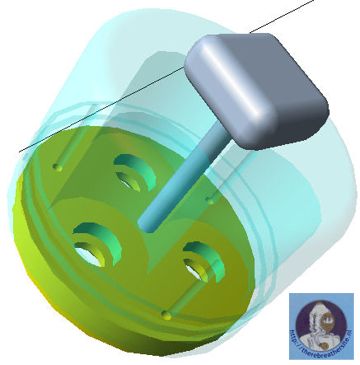

d.) O2 sensors: The sensors must stay in the RB. So I need a way to protect them while cleaning. I positioned three, as triangle, in housing and used a 45 degrees turnable “plate”, with three holes, in front of them as a valve. The trick is that the sensors are screwed through the plate so they overlap ca 1.5 mm. Then it is enough to place O-rings around them. The O-rings stay in position. Pressing the plate again these O-rings gives a nice, watertight construction. You can easily test the tightness by closing the valve and wait a couple of hours. You will see your ppO2 falling. |

|

|

e.)

O2 Measurement |

|

f.)

Cleaning and service |

|

Conclusion and what I would consider for next RB

I’m quite happy with the result. Maybe it’s

a bit to wide > water resistance!

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

On the image you see two black parts.

The big one is to close the scrubber

airtight when dismounted with still usable chalk. I have good

experiences by

Used coloring chalk to test that I never

came near to the end.

2. small one I use to hover my scrubber. I

started from first day to fill my scrubber as it has to be.

While a holiday in

by reverse blowing the dust out of the

scrubber via normal diluent… Using a blow tube, I had with me L

And last I have on my breathing tube

additional 2x 300g weights. That way the tube is more on your

shoulders. I find that nicer to dive and astonishing less water

resistance. |

|

|

|

|

rail for weightsystem |

|

|

|

|

weight system |

|

|

|

|

Accu pack |

|

|

|

|

|

|

|

|

Gasaddition |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Michael, thanks for sharing this information with us! | |

| For additional information please check michael's website here | |

| page made 27-01-2008 | |

| Menu homebuilders | |

| Please sign my Guestbook | |

| Email: jw.bech@quicknet.nl | |

Michael is a person who build his own CNC drill, his own CD label printer and did many other inventions. Of course he then start building rebreathers. After the MeCCR followed the MeCCRV2. Please enjoy the design steps of the Swiss MeCCRV2. I would like to thank Michael to share his thoughts and building efforts with us!

Mainmenu:

Search this Website

Information about RB

Photo galleries

Historical Information

Links & Downloads

Reviews

Homebuilders

Electronics

Updates, speed menu

Web shop

Reviews SC rebreathers

Reviews CC rebreathers

RB’s through the ages

Inspiration rebreather

Database Oxygen RB’s

Database Semiclosed RB’s

Updates

Speed menu

Search this web