|

THE DESIGN OF THE ELECTROLUNG

BY

Walter Starck

July 1998

I Sensors

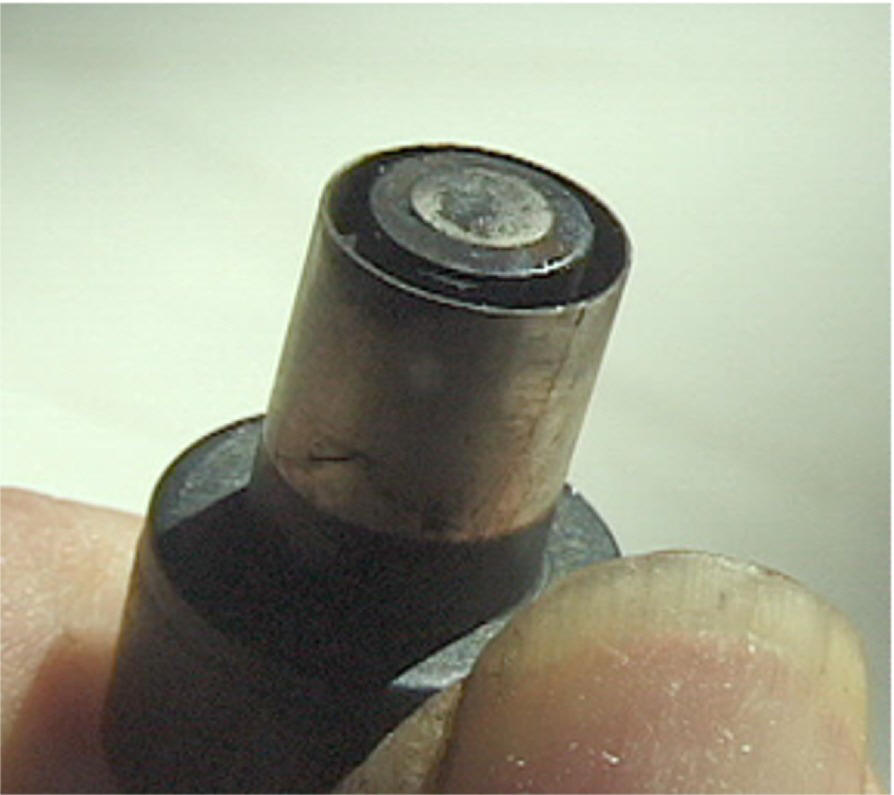

The Electrolung used

three polariographic oxygen sensors. The sensors were robust

handmade ones we made ourselves. They had a central platinum

cathode about 1/4" in diameter surrounded by a concentric silver

anode about 3/8" Diameter. In between was an annular groove for the

KOH electrolyte. A .001" teflon membrane held in place by a thick

silicone rubber boot retained the electrolyte. Although the sensors

would run for weeks before desiccation of the electrolyte became

limiting our SOP was to make them up fresh and calibrate them for

each days diving. At the end of the days diving the membranes would

be removed and the sensors washed with distilled water. Making up

and washing off the sensors only took a few minutes and assured you

always had fresh sensors.

Sensors of this type

don't wear out so they were hard wired into the circuit. Unlike

galvanic sensors they don't use oxygen but rather just respond to

its presence. They work equally well submerged so the effect of any

condensation is negligible. A drop of water fully covering the end

of the sensor would only slow the response time. It practice we

never had any condensation in the sensor area as this came

immediately after the canister so the gas was at its warmest and

driest point in the circuit. Thick plastic walls probably helped

too in avoiding condensation on cold surfaces.

The chief advantages of

the sensors were that they were always fresh and condensation wasn't

a worry. The disadvantage is that in making them up with fresh

electrolyte you can screw up by contaminating the sensor via sloppy

technique. Any significant change in calibration after a fresh make

up would be an indicator and determining why should be mandatory

before proceeding further. Still, there are the black box

mentalities who will simply crank the trim pots until they get the

reading they want and then assume all is well.

There were two trim

pots for calibrating each sensor. One for zero, the other for gain.

Zero was checked each time before the sensors were made up. Gain was

calibrated initially with air then the unit was put together and a

check with pure O2 was done. The permeability of Teflon to O2

varies with temperature. The sensors were of potted epoxy

construction with the electrodes embedded in the epoxy. A

thermistor in contact with the

underside of the

cathode was also embedded. This thermistor had a similar response

curve to the teflon and compensated for the temperature effect

keeping output linear over the desired range. Our chosen set point

was 0.5 Atm PPO2. The bottom line was that with proper care the

sensors were very reliable. Enough so, that they could be hard wired

in and I know of no case where one ever had to be replaced.

II Electronics

(control, readout, alarm)

Unlike galvanic

sensors, polariographic electrodes don't generate electricity.

Rather, the conductivity of the cell varies in the presence of

oxygen. A bias potential from an external source is applied between

anode and cathode and the resulting flow of current is a function of

the molecular concentration of oxygen present. The current

involved is very small so an Op Amp is used with each sensor to

boost power to a level useful for control and monitoring.

Hermetically sealed trim pots which incorporate an O-ring seal

around the adjustment screw provide for zero and gain adjustment of

each Op Amp thus enabling calibration.

The amplified signal is

read out to a wrist display, consisting of a stack of three edgewise

panel meters. 100 microamp meters were used in conjunction with

high resistance to prevent a possible short in this circuit from

affecting the solenoid control. Mil Spec, so-called "shock

resistant" meters were used. These resist minor bumps but still

they won't stand up if you drop the display on a steel deck or

concrete. In practice it wasn't a significant problem but

occasionally a meter did require replacement. This was quick and

easy to do.

The big advantage of

this type of analog display is, that you can tell at a glance

everything you need to know. In use all you need to verify is that

all of the readouts are in line with one another and at or a bit

above the set point which was exactly mid scale. This kind of meter

is also precise enough for calibration purposes. If I were doing it

today I would look at bar type LCD or LED readouts for monitoring

and perhaps a separate switchable numeric display for calibration.

I would also seriously consider a miniature head up display in the

mask instead of one on the wrist. I don't like numeric displays for

monitoring as they entail reading and mentally comparing numbers

which requires much more attention than just noticing if position

and alignment are where they should be. Possibly some of the

commercial RBs have already done all this.

The amplified signals

from all three sensors were fed into a fourth Op Amp which in effect

averaged them and used the resulting value to control the solenoid

set point via a switching transistor. We used a fixed set point of

0.5 Atm PPO2 but it would be simple to add a trim pot to provide an

adjustable set point. Clipping circuitry limited the input to the

control Op Amp from each sensor to values corresponding to 0.25 and

0.75 Atm PPO2. If any one sensor began to read drastically different

from the others its effect on automatic solenoid control was thus

limited. Clipping came after the meter display thus they would

continue to read true output even if the input to the control Op Amp

was clipped. Clipping also activated an audible alarm. If the

alarm sounded a glance at the meters would tell you what the

situation was. If only one was off the other two would continue to

exercise control. If all were high, low or different from one

another you could use manual control while aborting the dive.

The Op Amps require a +

and a - voltage power supply. This was supplied by a pair of 9V

Manganese Alkaline transistor radio batteries. Bias to the sensors

was provided from the same source via a voltage dividing resistor

circuit. A second pair of the same batteries provided switchable

backup power. A third pair used in parallel provided separate power

for the solenoid. The solenoid did not have backup as this is

non-critical because manual control of O2 is easily effected. The

snap terminals used for this type of battery were securely attached

to a bulkhead. A screw adjusted base plate held the batteries

firmly in place and against the terminals avoiding any possibility

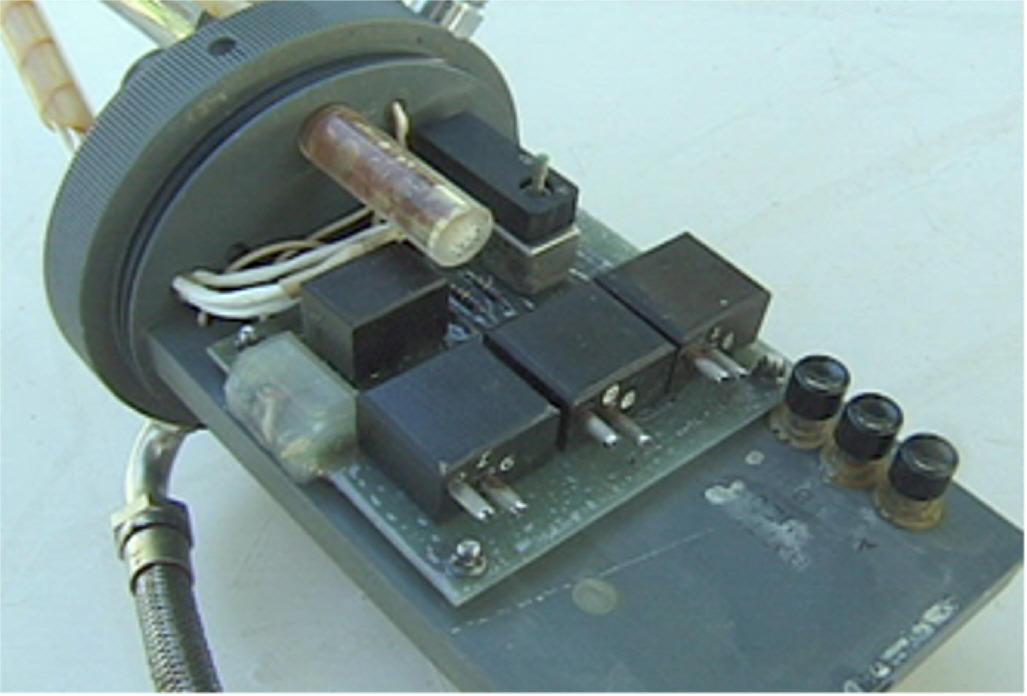

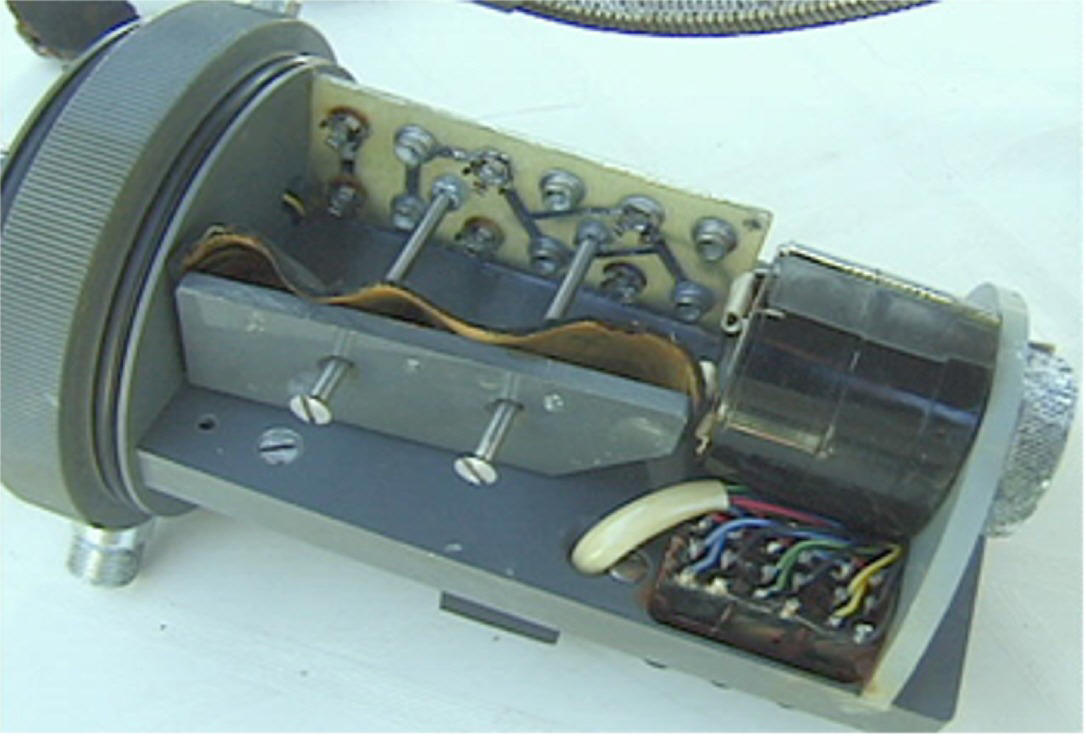

of a loose battery connection. All the electronics were incorporated

on a single circuit board about 4x5". This was mounted on one side

of a longitudinal bulkhead in the electronics housing with the

batteries and audible alarm on the other. This longitudinal

bulkhead was itself mounted on a transverse bulkhead which separated

the electronics compartment from a plenum above the absorbent

canister. The solenoid and sensors were mounted on the opposite

side of this transverse bulkhead thus everything electrical other

than the wrist display was immediately adjacent to each other.

In the units I made all

of the electronic components were on a printed circuit board. After

assembly the boards were coated with a spray-on waterproofing

compound as is widely used for marine electronics. At Beckman the

components were assembled into 4 micro- welded epoxy potted modules

which plugged into gold plated sockets on the circuit board. In

theory this is a better way to go but in practice it didn't make any

noticeable difference.

With respect to

reliability of electronics in this kind of application. Recently

someone posed the question of when was the last time your TV failed

to which Robert made the wonderful reply, "The last time I took the

bastard underwater." Both comments reflect important points.

Electronics in themselves can be extremely reliable. In terms of

MTBF, far more reliable than most mechanical devices. Enough so

that they can be trusted for things like passenger aircraft control

systems where thousands of systems are in everyday use and a single

failure means the loss of hundred of lives. But Robert is right

too. If you flood them with water they fail. The problem then is

really a mechanical one. Can electronics be reliably enclosed so

as to prevent flooding in underwater use. If it were solely a

matter of constructing a watertight pressure proof housing for the

electronics that alone wouldn't be too hard. Unfortunately there is

also the matter of connections for sensors, displays, a solenoid,

and a switch plus keeping all these external devices themselves

dry. The possibilities for leaks begins to multiply. With a great

deal of care in construction and use, high reliability is achievable

but I think there is a much easier way to reliably keep out the

water.

The key to the solution

is pressure. Keeping things watertight under 100-200 psi is

difficult. Doing it under 0.5-1 psi is easy. In the Electrolung

everything was at ambient pressure. The electronics compartment was

vented via a small canister of silicagel with the rest of the

system. A standpipe for the vent orifice prevented any accumulated

moisture in the canister plenum from being pushed into the

electronics compartment. In anything but a head down position the

electronics were above the counterlung thus any leak would normally

result in gas escaping rather than water coming in. In practice

with the kinds of seals involved and the very low pressure

differentials leakage anywhere in the electronics section was never

a problem.

III Gas supply

Two, 9 cf., 2100 psi steel

gas cylinders were used for O2 and inert gas. These were lightweight

models FAA certified for use in aircraft. Initially we used chrome

plating to protect them, later we went to teflon coating. Beckman liked

the more military look and there was some concern over possible hydrogen

embrittlement from the chroming process.

Standard,

old style, "K" valves were used as cylinder valves. On the inert

side a SCUBA regulator-type yoke was used to mount a high pressure

1/8" NPT needle valve operated by rotary action of a T-shaped

handle. Inert gas was valved in manually directly from the tank as

needed using this valve. In use it had a very smooth precise feel.

Inert gas was valved into the plenum at the bottom of the absorbent

canister so that some mixing would take place before it got to the

sensors.

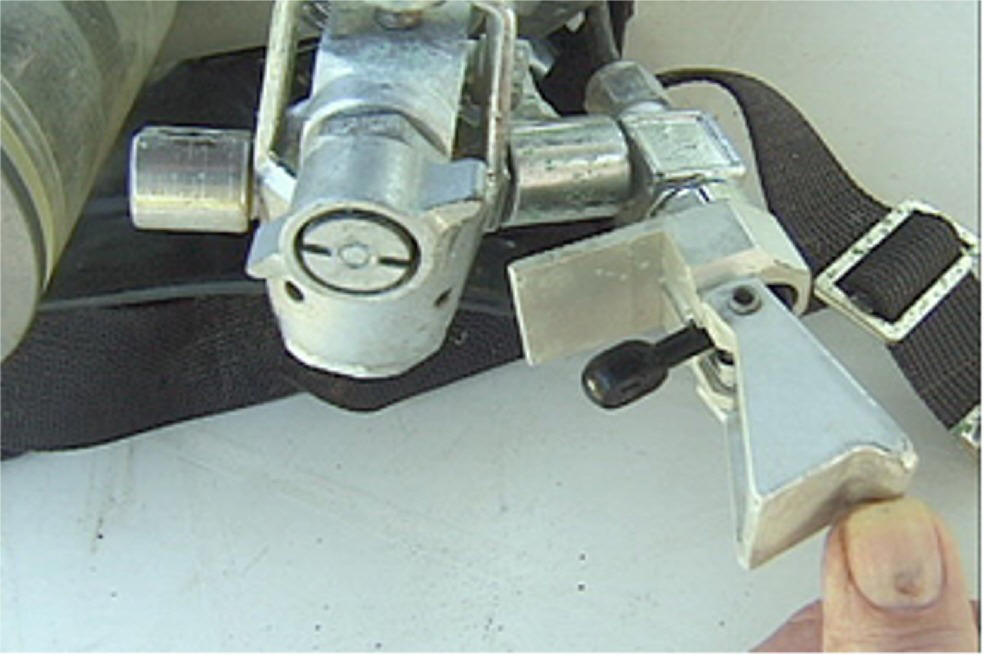

On the O2 side a piston

type first stage of a U.S. Divers single hose regulator was used to

reduce tank pressure to about 60 psi. This is somewhat lower than

such first stages normally deliver and was achieved by using a

weaker piston spring. The normal hose to the second stage was used

to connect the O2 supply to the solenoid valve. The octopus port of

the first stage was used to attach an O2 bypass valve. This was a

spring action, lever activated low pressure valve and it was

protected by an enclosure which required opening a spring closed

cover to get at the valve. The manual bypass valved O2 directly into

the sensor compartment so the result was immediately readable.

I will digress briefly

on O2. In addition to the physiological risks recently discussed in

some detail on the list there is also the danger of fire and

explosion. Valves, regulators, fittings and any other equipment

used for O2 have to be thoroughly degreased of any petroleum based

lubricants. If lubrication is required, as for example with the

o-ring seal

of a regulator piston,

non-combustible silicone based lubricants must be used. Be aware

that even a fingerprint oily with suntan lotion can start an

explosive fire with O2. Once an O2 fire starts all sorts of things

you might not ordinarily think of as combustible burn ferociously.

I have heard stories of chamber fires in which everything inside,

including the occupants, was reduced to ash.

My partner Kanwisher

was on one of the advisory panels to NASA in connection with the

Apollo program. Although he recommended using a mixed gas

atmosphere in the Apollo capsule he was over-ridden by the engineers

who felt that monitoring the PPO2 was too difficult. John knew

better as he had been doing it for several years in conjunction with

his work on respiration but the engineers prevailed. The result was

the fire which killed three astronauts.

The solenoid valve we

used was a miniature 12 volt one made for pneumatic control. We

equipped it with a miniature screw adjusted needle valve outlet.

When the setpoint is reached and the solenoid is triggered it takes

perhaps three or four seconds for the sensors to respond and rise

enough to cut it off again. The solenoid needle valve was adjusted

so that the O2 injected raised the PPO2 to a peak pulse of about

0.75 Atm and would usually

trigger a couple of

beeps from the audible alarm. Within a couple of breaths mixing

brought the level back to perhaps 0.65 after which it dropped more

slowly as it was consumed by metabolism until the setpoint was

reached again after about a minute or so. That would be for

moderate activity such as easy swimming. At complete rest it would

of course take longer to drop back to the set point and less time if

you were actively swimming.

If the needle valve was

adjusted to a lower flow rate solenoid activation would be more

frequent and of longer duration placing an unnecessary drain on the

solenoid batteries. If much higher flow was adjusted for the O2

spikes would be too high and the alarm would be sounding much of the

time.

I think there are now

smaller, more power efficient solenoid valves available.

The solenoid and manual

bypass valves were of the downstream type so that if high pressure

leakage from the regulator occurred it would release when it reached

the level where it overcame the spring tension which normally closed

the valve. This is important to prevent either valve lockup or

blowing out the supply hose in the event of a high pressure leak.

In the event of O2 leakage from either valve the cylinder valve

could be used to cut it off.

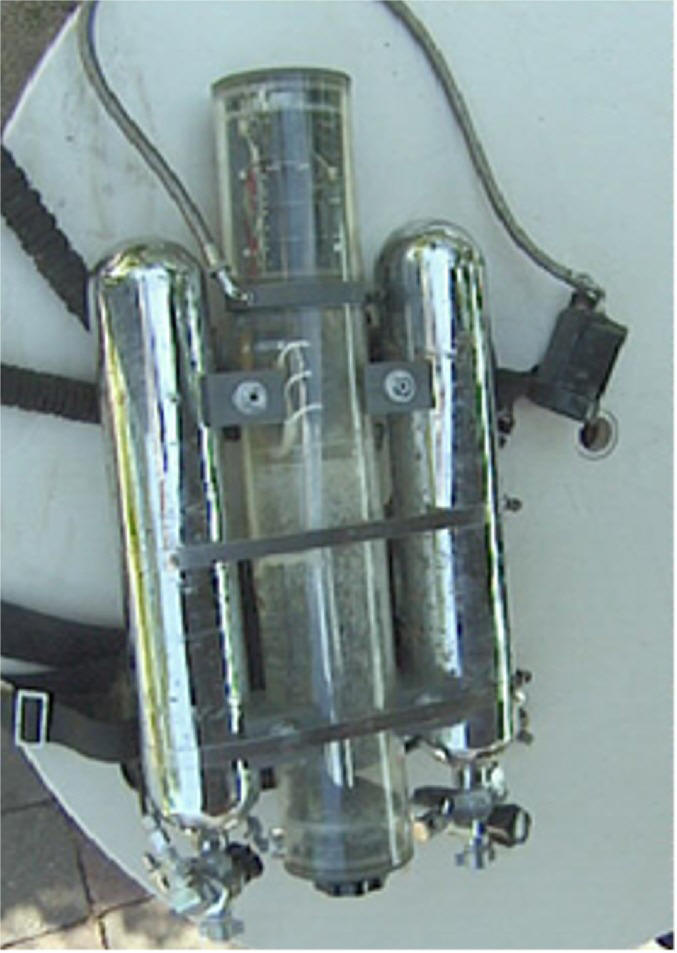

The gas cylinders were

mounted on either side of the central larger cylinder containing the

absorbent canister and electronics section. This assembly was worn

as a back pack with the valves at the bottom at hip level. Inert gas

had to be added several times on descent and at other times if you

lost any from nasal exhalation. Manual O2 was normally only used in

decompression. The inert gas valve was therefore on the divers left

side leaving the right hand free for more complex tasks. Swapping

sides for southpaws would have been easy but I don't recall anyone

ever raising the question. It was no big thing either way.

IV The breathing

circuit (mouthpiece, hoses, counterlung, canister)

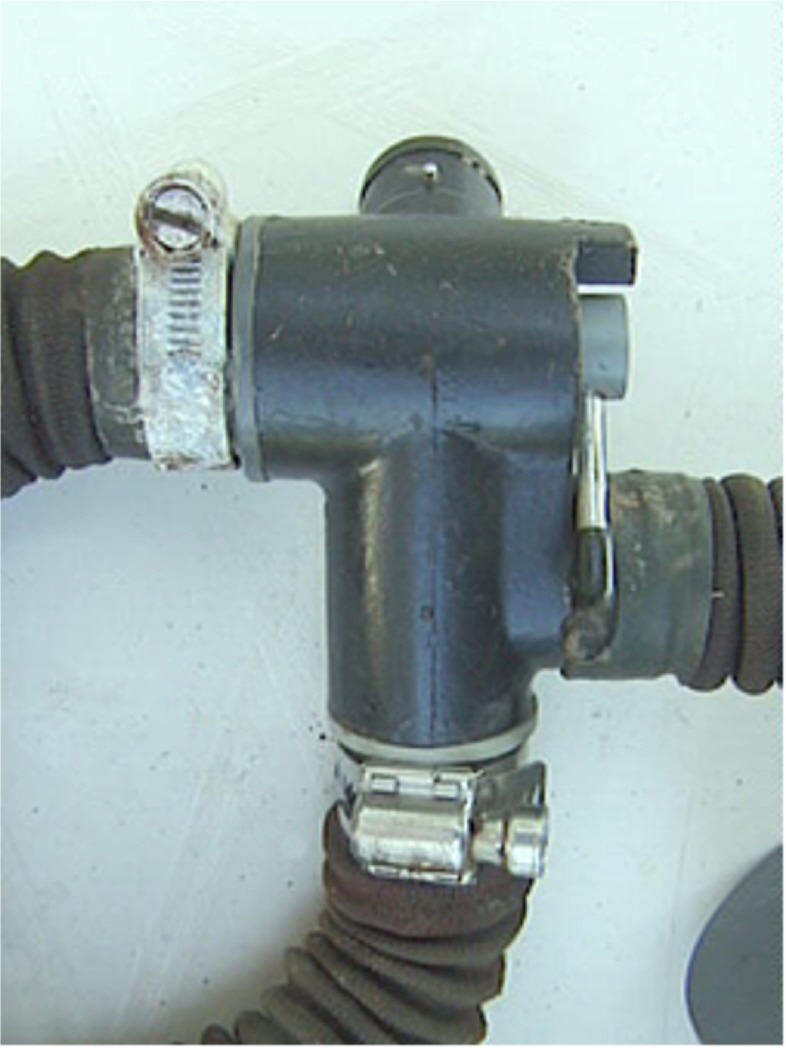

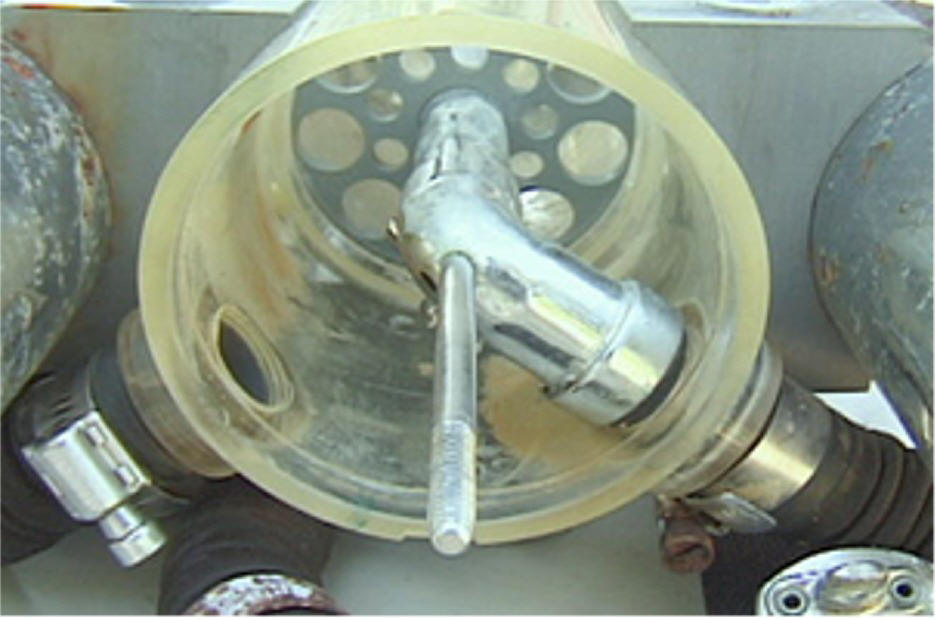

The Electrolung

mouthpiece was originally constructed of PVC. The main body of the

mouthpiece assembly was made in three parts fuse glued with PVC

solvent cement. At Beckman this part was manufactured as a teflon

coated aluminium investment casting which made a nicer looking

part. A rotating drum type valve operated by a small lever

permitted closure of the mouthpiece if you wanted to take it out of

the mouth underwater. Two check valves directed gas flow to the

proper hoses for inhale and exhale cycles.

Three breathing hoses

were attached to the mouthpiece. One went straight down to the

counterlung which was worn on the chest. The other two went to

either side over the shoulders to the inlet and outlet of the

absorbent canister/electronics section which was worn on the back.

Initially hoses from the old style twin hose scuba regulators were

used. At Beckman we found a manufacture in L.A. who made high

quality fibre reinforced hoses for the O2 breathing systems in

military aircraft. The price was only a little more than the scuba

hose and they could be made to order as to length in small

quantities. Scuba hoses tended to start to leak after a year or

two. The others are still usable after a quarter century in tropical

conditions.

Hose clamps may seem

mundane but are worth considering. A hose coming off with scuba is

an inconvenience. With a RB it is a life threatening disaster.

Initially we used the spring steel ratchet type clamps used on scuba

regulators but I didn't fully trust them and they rusted. We tried

chrome plating them and found they would then break unexpectedly due

to hydrogen embrittlement. In the end we went to good quality heavy

duty SS worm screw type clamps. Some SS clamps have ordinary mild

steel worm screws which rust, electrolyse, and break after awhile in

marine use. Light weight SS clamps can also break for no apparent

reason due to stress fatigue. SS is prone to this. SS fitting used

in sailboat rigging are notorious for letting go at the most

inopportune times.

A lot of people seem to

now use the nylon ratchet type ties for clamping hoses but I

wouldn't trust these either for critical applications. Nylon is

subject to cold flow under stress and after a while they become

looser.

Using them as a back up

next to a good SS clamp however might not be a bad idea.

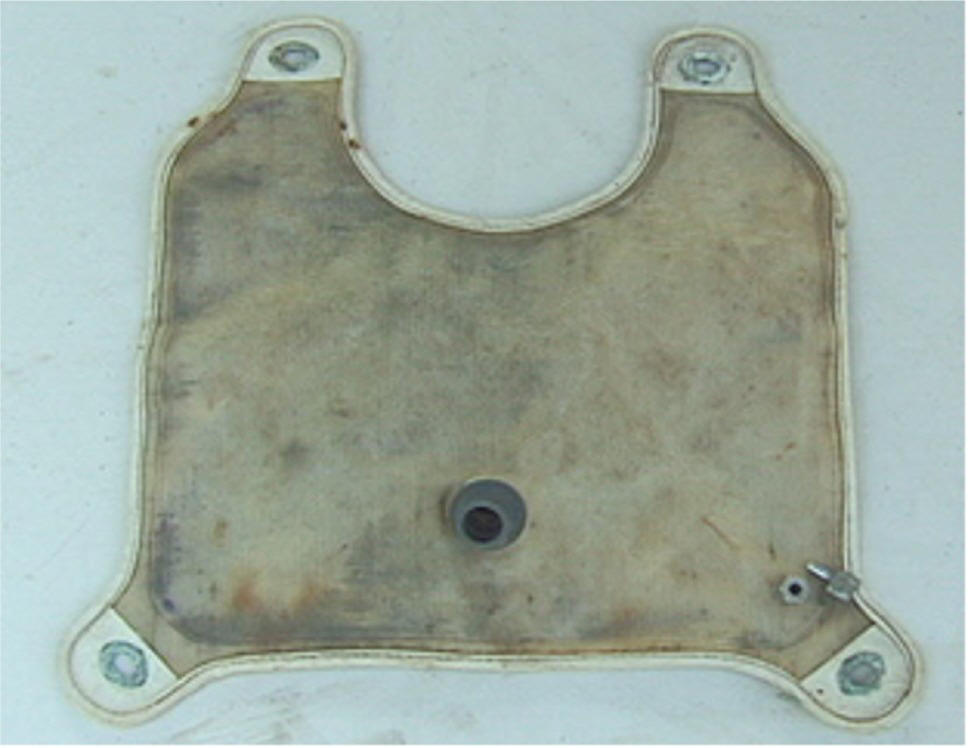

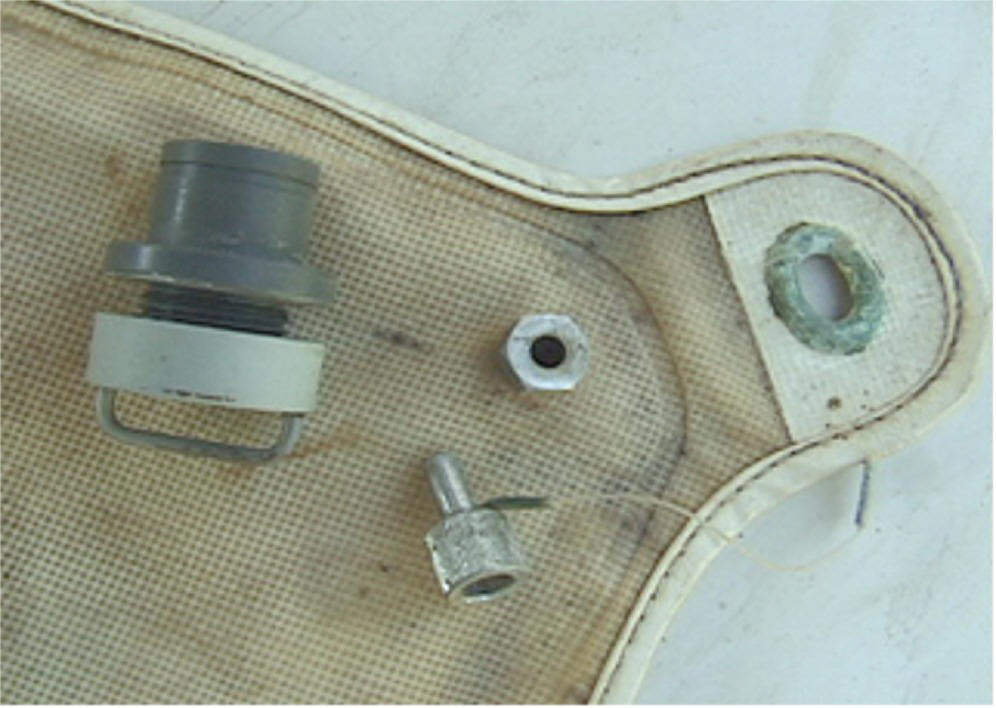

The counterlung was a

bag made of two pieces of plastic material electronically welded

together over a 1/4" surface around the entire perimeter about 1/2 "

in from the edge which was then sewn together wrapped in a heavy

edging tape. Originally I used clear vinyl for the material.This

worked well enough but later I found a lighter, more flexible,

translucent fibre reinforced plastic material which was better.

Being clear or

translucent offers two advantages. It lets light in and so reduces

the growth of micro-organisms. It also makes it easy to see if any

water has accumulated and get rid of it before it gets to a level

where it might be drawn into the absorbent canister. Places which

make awnings, boat covers, etc. or those who make plastic zipper

bags ,folders and the like can easily and inexpensively do this kind

of work. All you need is a paper pattern of what you want.

One-offs for prototyping are not expensive and with a $100 or so for

a die for the welding they can pop out small quantity runs dirt

cheap. Usually they also have samples and catalogues of all sorts

of material to choose from. Teflon coated nylon is now available

and might be very good for this application. I mention all this

because some homebuilders may be interested.

The counterlung had a

single hose attached about 1/3 of the way up from the bottom on the

front (away from the body) side. A drain plug was at the bottom

near the lower left corner. At Beckman we added an overpressure

relief valve near the top. The fittings all used a flange and

threaded collar type attachment similar to a kitchen sink drain.

The flange incorporated a groove and o-ring in its face which

ensured a firm grip and seal with the counterlung material. The

fittings were machined from PVC except for the small drain fitting

which was SS or chromed brass with a 1/4" plug on a short lanyard.

It was basically the same as a control gland used in underwater

camera housings.

The overpressure relief

valve released at somewhere around 0.75 psi. Its only practical use

was the prevention of possible counterlung rupture if gas was

accidentally valved in with the mouthpiece shut-off valve closed.

It was introduced at the suggestion of experienced OC divers who not

being used to getting rid of excess gas via the nose during ascent

tried to exhale against a full counterlung and couldn't.

The counterlung was

attached by grommets at each corner which mated with twist studs

mounted on the shoulder

straps at the top and on short adjustable straps paralleling the

backpack waist strap on each side at the bottom. The counterlung

volume we used was about 4 L.

There has been some

discussion on the list recently re: the relative merits of chest

mounted (resistance on exhale) Vs. back mounted (resistance on

inhale) counterlungs. In an earlier post, which has been quoted in

the recent discussion I opted for chest mounting as preferable

because the mechanics of breathing musculature is such that the

power available for exhalation is greater than that for inhalation.

The counter argument is that resistance on exhale reduces the volume

of exhaled gas leading to CO2 retention.

First, we need to keep

in mind all this is somewhat hypothetical and in the real world both

configurations have been used successfully. With sustained high

level exertion where any advantage might be important (and in the

continuing absence of any proper comparative testing) I would opt

for the chest mount for two reasons. It's less tiring to put a bit

of extra effort into exhaling than it is into inhaling and the

bottom line at the extreme for ventilation lies with how much gas

you can move in and out in a given time. Given equal resistance in

either direction the more powerful exhalation cycle will move the

greater amount of gas. In the end, over a few breaths, expiration

and inspiration must be equal. Restriction of either sets the limit

so if there has to be a restriction I would rather it be on the side

which can best handle it.

We sold a number of

Electrolungs to commando type users. One of their prime concerns

was breathing resistance in sustained hard swimming. After trying

it, all gave it their thumbs up in this respect. In out of water

chamber tests at 1000 FSW pressure breathing resistance during

exercise was encountered. This was in the breathing circuit itself

and could of course be relieved somewhat by bigger hoses, larger

absorbent bed cross section, etc but as the market for that

capability was effectively nil it was never pursued.

One memorable

experience with the commando types took place in the Bahamas. A

British Royal Marine Commando attached to the Canadian Navy flew

down to join me on my vessel and try out the Electrolung. He was a

big bullet headed guy, built like a fridge with a head. After a

couple days instruction diving he wanted to do a long hard swim with

it and as there was no one else to do it with him I ended up going

along. He went for a couple of miles virtually flat out. Luckily

the water was crystal clear so I managed to at least keep him in

sight. When we came to the surface the bastard wasn't even winded.

He was satisfied it could do the job and just wanted a smoke. It

was flat calm and the water was only about 30 feet deep so I had a

skiff following us with his smokes and we could ride back.. Although

I still don't know for absolute certain whether chest or back mount

is optimal I do know that chest mount is good enough. What I really

do like about it is that it is easy to see if there is any water in

it and easy to pull the plug, squeeze the bag, and expel it. We did

have a couple of experienced OC divers, new to the Electrolung, let

water leak in around their mouths until it was gurgling away with

each breath. They continued until they had largely flooded the

absorbent canister and eventually got a mouthful of absorbent

cocktail. They were quite irate about all this and swore it was the

fault of the Electrolung. This kind of thing is a recurrent problem

with RBs. Experienced OC divers have habits which don't go with RBs.

They also tend to think of themselves as expert divers rather than

as novice RB users. As a result they often don't really listen and

take advice well and tend to blame the device if anything is not

right rather than realising that they have to learn to use it right.

The actual breathing

circuit for the Electrolung was: Exhale directly to counterlung via

bottom mouthpiece hose. Inhale draws gas from counterlung back out

the same hose into left mouthpiece hose thence to the bottom of the

canister via a central tube inside it. At the bottom the gas

emerges into a plenum which distributes it over the inlet surface of

the absorbent column. After passing through the absorbent it emerges

at the top into the chamber where the sensors and solenoid are

located. From here it continues via the right mouthpiece hose into

the mouthpiece itself.

V Absorbent canister

/ Electronics housing

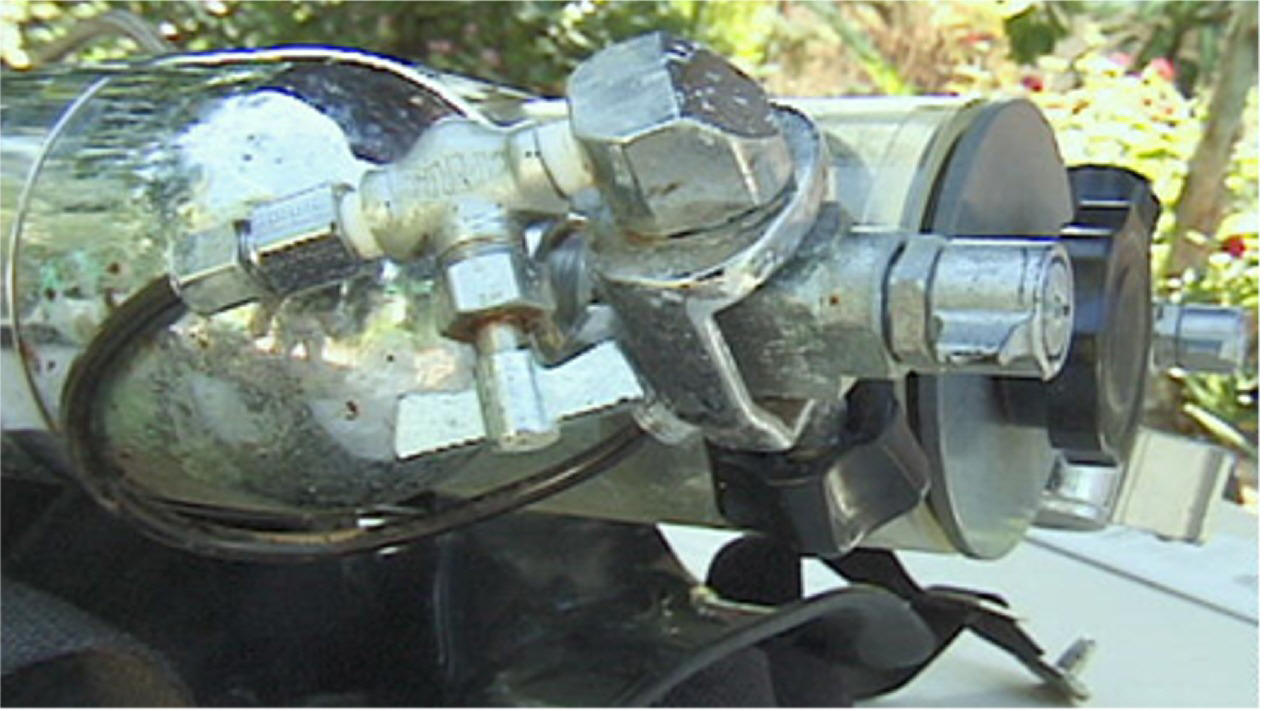

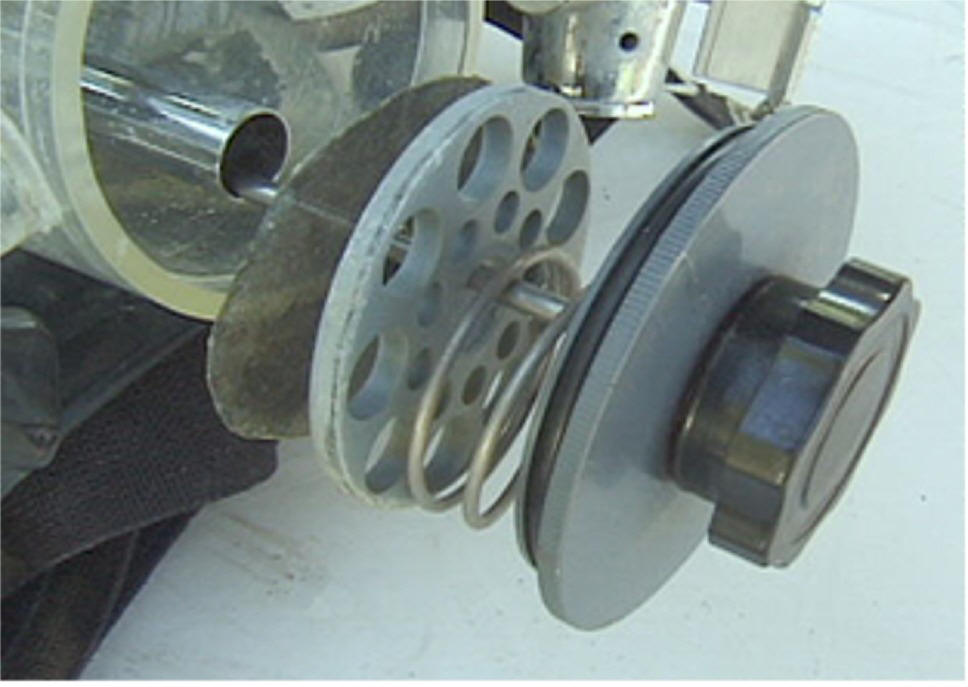

In the Electrolung the

CO2 absorbent and electronics were housed in a transparent acrylic

(Plexiglas) cylinder which together with the gas bottles was worn as

a backpack. This cylinder was 24" long x 4" I.D. with 1/4" thick

walls. It was divided into two pieces. An 18" section contained

the absorbent bed with a 4" space at the top which accommodated the

sensors and O2 solenoid. A 6" section at the top contained the

electronics. A small knob on the electronics section operated a

double throw, center off, switch controlling power to the

electronics via either set of batteries. This was reachable behind

the head if development of your biceps didn't prevent it.

Actually geeks do

make the best RB divers anyway but out of respect for the temporary

cease fire I will refrain from further comment along that line.

The ends were sealed by

1/2" thick PVC O-ring sealed plug type closures. A thick PVC double

plug type bulkhead joined and partitioned off the electronics section

from the absorbent section. The entire assembly was held rigidly

together by a central 1/4 SS tie rod running from top to bottom. It had

a large external knob at the bottom for tightening and loosening which

was effected by screwing into a metal socket on the top closure. O-ring

seals were used to seal the tie rod penetration of the bottom closure,

the metal tie rod socket on the top closure and where the tie rod passed

through the electronics bulkhead. This last was only to prevent

capillary action from possibly drawing any water from the absorbent

section into the electronics section.

The electronics section

atmosphere was vented to the absorbent section through a small

canister of silica gel via a separate bulkhead penetration and a

small standpipe as mentioned earlier in the description of the

Electronics.

The O-ring seals for

the end closures and the join at the electronics bulkhead were all

radial type seals which automatically effect a proper seal when they

are plugged into the cylinder. Sealing is effectively independent

of how tightly or loosely things are clamped together. With this

type of seal and operating at ambient pressure the possibility of

leakage around a seal is vanishingly small.

A brief aside for

homebuilders. Although O-rings are marvellously effective seals and

are universally used in all types of underwater equipment it is

remarkable how often manufactures use them improperly. O-ring

suppliers have various free pamphlets and data sheets on proper

application of O-rings which includes data on the correct shape and

tolerances for the grooves which accommodate them. It is well worth

while to avail yourself of this information.

Common errors in O-ring

usage which you often see in marine equipment are: Grooves too deep

resulting in inadequate sealing pressure. Too shallow, resulting in

too much compression of the seal leading eventually to fine radial

cracking and consequent leaking. Too narrow, which interferes with

proper compression and sealing at low compression, and distortion

toward a square cross section under full compression, this leading

again to radial cracking of the seal. Finally, and most ignorant of

all, is the use of rounded U-shaped grooves which defeats the whole

principle and advantages of the circular cross section and turns it

effectively into a flat gasket.

The absorbent canister

portion of the cylinder was a 12" section toward the bottom defined

by two 1/4" thick acrylic or PVC internal bulkheads perforated with

an array of holes. Plastic screen was used to keep the absorbent

from falling through the holes. The top bulkhead was fixed in

place. The bottom one was free to move but held in place against

the absorbent column by a large spring. This served to keep the

absorbent compacted without channelling despite any minor settling

of the granules after filling the canister.

We used Barylyme as an

absorbent. This is a National Cylinder Gas trade name for Barium

Hydroxide. It was widely used in hospitals and came in hermetically

sealed one quart cartons of the type used for milk. The Electrolung

canister held two cartons which would be sufficient for six hours of

moderate activity. We changed them after four hours. Barylyme came

with a colour indicator, pink when fresh, blue when expired. It is

less caustic than soda lime and worked well for us.

As described earlier

gas was drawn from the counterlung to the space at the bottom of the

canister down a central 1" ID tube leading from the inlet hose

attachment down to the bottom end of the canister section. From

there it passed back up through the absorbent into the

sensor/solenoid chamber and on via the inhale hose to the

mouthpiece.

The gas supply

cylinders were mounted on either side of the absorbent

canister/electronics cylinder using spacer blocks conforming to the

curvature of the respective cylinders. The three cylinders were

secured rigidly in place by two large SS hose clamps. One was

adequate for the purpose so there was backup in the event of one

breaking. The spacer blocks also served as attachment points for

the harness which was a U.S. Divers one of the type widely used

before BCís took over this function. There was a wide vinyl strap

for each shoulder plus a waist strap. The overall configuration of

the Electrolung backpack was similar in many respects to that of the

small triple tank OC rigs favoured by the French at that time. It

rode well on the back and was quite comfortable. All up weight of

the Electrolung was about 30 pounds.

Some people expressed

concern about the use of acrylic fearing the possibility of

breakage. This is one of those things which is more apparent than

real. In this case it is protected on one face by the wearers body,

on either side by steel gas cylinders and at top and bottom by thick

PVC ends. The only real exposure to any possible impact was the

curved surface of a 4 1/2' OD 1/4 thick cylinder which would be

extremely hard to break. We did look at using polycarbonate (Lexan)

which is literally bullet proof but found it crazed and crumbled

into small pieces when exposed to hydroxides. It would of course be

easy to make the whole thing of PVC but I feel the advantage in

being able to see condensation, water, and the condition of your

absorbent more than outweighs the non-problem of smashing heavily

into things while going backwards. Beckman offered a fibreglass

fairing for those who might be concerned with this but of course

some then bought it because they liked the way it looked and others

did so because they felt that if it was offered they probably should

get the complete set up.

A final aside for

homebuilders. The Electrolung was really a homebuilt which became a

commercial product. It was built entirely with a drill press,

lathe, and jigsaw; plus a bench grinder for shaping and sharpening

lathe tools as the only power tools. For anyone attempting to build

any kind of underwater equipment a metal lathe is really a must.

With one you can easily make all kinds of cylindrical housings,

O-ring sealed fittings, ports and closures, and any kind of threaded

fitting you might need. A small lathe with a five or six inch

swing over the bed will enable you to make housings and ports up to

10-12" in diameter. Good quality Chinese made lathes suitable for

this kind of work are now available for about U.S. $ 1500. For

another few hundred dollars you can also get a milling attachment as

well which is a useful addition.

Teaching yourself how

to use it is not hard. Good text books which cover this kind of

machine tool work are readily available and easy to follow.

The Electrolung patent

is online at

http://www.patents.ibm.com/details?patent_number=3727626

The online material is

a summary but you can order the full patent there. It contains much

more detail including various drawings.

VI. Final (Reflections and speculations)

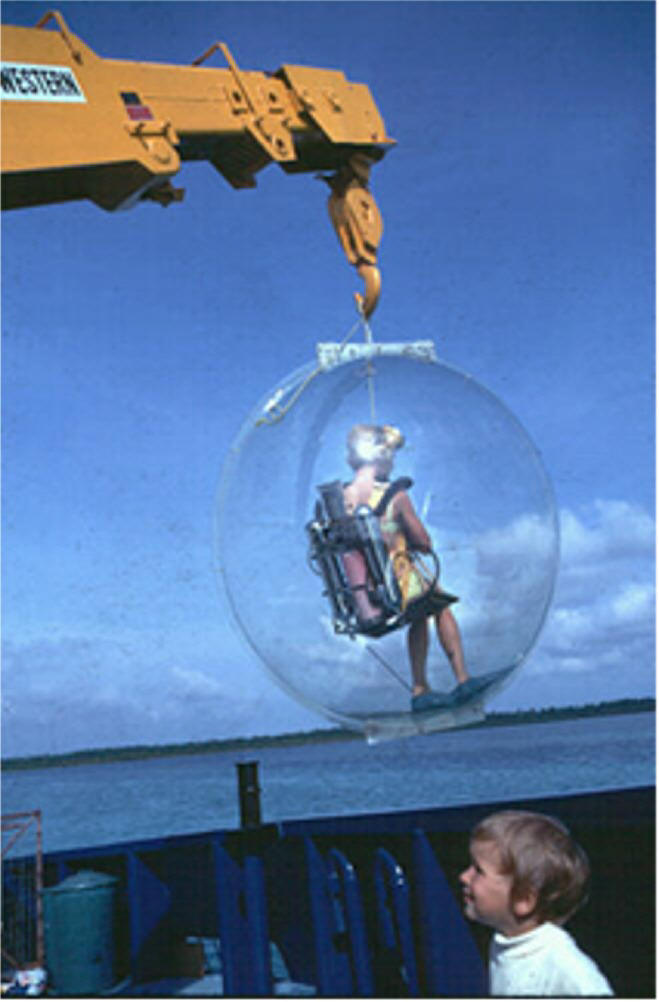

Development of the

Electrolung came about through the chance meeting of John Kanwisher

and I aboard Ed Link's diving research vessel in the Bahamas in

early 1968. Ed was trying out his new diver lock-out submarine Deep

Diver and had invited along several researchers with relevant

interests. I was there to do some deep biological collecting and

John was there to do heart rate/respiration measurements on divers

using some new acoustical telemetry equipment he had developed.

Lock-out dives from

Deep Diver were done using hose fed OC Kirby Morgan helmets. Gas

for this purpose and to pressurise the lock-out chamber was supplied

from a large high pressure sphere carried by the sub. The large

amount of gas required for a single dive severely limited the number

of dives which could be made and involved substantial cost and

logistic considerations. The need for more efficient utilisation of

gas was clearly apparent.

It turned out that John

and I had both been considering the feasibility of a mixed gas CCRB

using electronic sensors to control PPO2. We both knew in general

terms what was needed but John wasn't a diver or a machinist and I

didn't know that much about electronics. However, I had been diving

for 15 years and had built a wide range of underwater equipment and

John, in addition to being a physiologist, had invented the first

polariographic oxygen sensor and held a dual appointment at Woods

Hole Oceanographic Institute and MIT where he lectured on electronic

instrument design.

When we returned to our

homes John started putting together the sensors and control circuit

and I started getting together the hardware and machining all of the

necessary bits. Six weeks later we both had our respective parts

together. John sent me the board and sensors, I installed them and

it worked. The overall configuration and design was basically as

described but there were, of course numerous details to clean up.

The electronics for example were wire connected on a breadboard and

the solenoid valve I had hand made and actuated with a solenoid

scavenged from a battery operated coo-coo clock.

Although the prototype

was put together quite quickly it was far from a "first thing which

comes to mind" effort. Quite a few years experience and thought had

led up to it so that when actual construction was began we both knew

pretty clearly what needed to be done and how to do it. Later at

Beckman I had the opportunity of working with a whole group of

specialists on improving the same device. The outcome was some

tidying up of details

but no fundamental

improvement. The biggest problem was to prevent the creation of

problems which didn't previously exist but could be introduced

through changes made by specialists who were unaware of consequences

outside of the narrow area of their expertise. The experience gave

me a real appreciation of both the power and the limitations of

specialist expertise and the importance of systems analysis in

co-ordinating and integrating the input of specialists.

Although development of

the Electrolung was interesting, even exciting, in itself it was

just an interesting incident in a bigger, far more interesting and

significant picture. Like most historical events, I suppose, what

was happening didn't appear to the participants at the time so

remarkable as it later does in the broader perspective of hindsight.

The larger perspective on what is taking place right now tends to

be somewhat obscured by the ordinary events of living. Except for

rare instances whatever we are doing, however interesting and

exciting it may be, tends to still feel like life, not like history

in the making.

In retrospect however,

I have come to realise that from the mid 1950 through the mid 70's

something really remarkable was taking place in diving. During that

period diving grew from the obsession of a small group of generally

impecunious young people mostly in FL, CA, France, and Italy to a

global industry catering to well-to-do hobbyists. Remote tropical

islands all over the world began to sprout airports and dive

operations and diving

became strongly

oriented to travel to exotic locations. Though all this was in

itself remarkable something truly unique was at the real heart of

what was happening.

For the first time in

history humans could freely enter, explore and personally experience

the oldest, richest, most beautiful and exotic communities in

nature, tropical coral reefs. Coral reefs are truly remarkable

places. Nowhere else can one experience such an abundance and

diversity of life. Nowhere else is it so colourful, exotic and so

easily experienced at close range.

Diving on a reef is

like a trip in a time machine to a time before humans existed and

nature ruled in primeval pristine abundance. Fossils of many reef

creatures from as much as 60 million years ago are essentially the

same as those on reefs now. In fact some Pacific reefs have existed

as reefs for that period of time.

For a biologist, being

among the first to dive on reefs was an extraordinary experience.

In a way it was a bit like landing on another planet. On nearly

every dive you were going where no human had ever been before. The

discovery of phenomena of life and strange and beautiful creatures

whose existence we never even suspected was an everyday occurrence.

At the time this kind of experience was so commonplace, tropic seas

so vast and remote, and so few people were doing it, that it began

to seem as if this was just the way things were and this kind of

experience would continue on indefinitely.

Already however, this

era has become history. Although there are vast amounts still to be

discovered about the details and inner workings of reefs, still

undiscovered species are getting harder and harder to find and

remote locations are becoming less and less remote. The experience

of being among the first to explore the richest realm of nature has

come and gone, not to be repeated.

On reefs, one niche

still remains. Actually it is a really big one. The zone below 200

feet, down to the deepest limits of what you might call part of the

reef community at about 600 feet, is still largely unexplored.

Although it is not so rich in life as the shallower regions it is

still rich in life and is an area about which we know very little.

As far as I am aware

the only person on the planet regularly exploring this zone is Rich

Pyle. What he is doing is really exceptional and he is doing it

essentially on his own. While discussion on the Rebreather List is

largely restricted to the technology and physiology as an end in

itself what Rich is doing goes well beyond this. As well as making

more deep free dives than anyone ever has before he is coming back

with knowledge and specimens from every dive. What he is doing is a

permanent contribution to knowledge which will stand long after any

of today's diving records are broken and

forgotten. I have never

met him personally and am commenting only out of recognition of

something exceptional.

Over the past 25 or

thirty years advances in diving technology have been almost

entirely small and incremental. The only real exception I can

think of is the development of dive computers. It appears we are up

against the realities of human physiology. With every increase in

depth and bottom time the cost, complexity , effort, and risk

increases exponentially while the return of useful achievement

remains more or less linearly related to bottom time.

The future it seems

lies in other directions, especially robotics. Here the advances

have been impressive and future development promises to become even

more so. Already we are at a point where more and more functions

previously requiring a diver can be effectively carried out by

ROVís . It is not hard to foresee that in a few years most of what

we do at great effort and risk by diving can and will be done by

nerds at consoles. In fact, right now in the Gulf of Mexico Shell

and BP are drilling in 5000 to 6000 FSW and all work at the

wellhead is done by ROV'S.

If you find this kind

of scenario uncomfortable, donít let it worry you. Long term

prediction, no matter how well reasoned and seemingly inescapable,

has a way of almost always being wrong. So much so that I have

often wondered if beneath the facade of Newtonian certainty of our

universe , somewhere in the iffy probabilistic realm of quantum

mechanics, there is not a relationship which dictates that the very

act of prediction sets in motion forces which generate a different

outcome. So if you donít agree with my prediction, the good news is

that I may well have voided it by predicting it.

Fortunately, the real

outcome is usually even more interesting than any of the

predictions.

Walter Starck

|