|

-

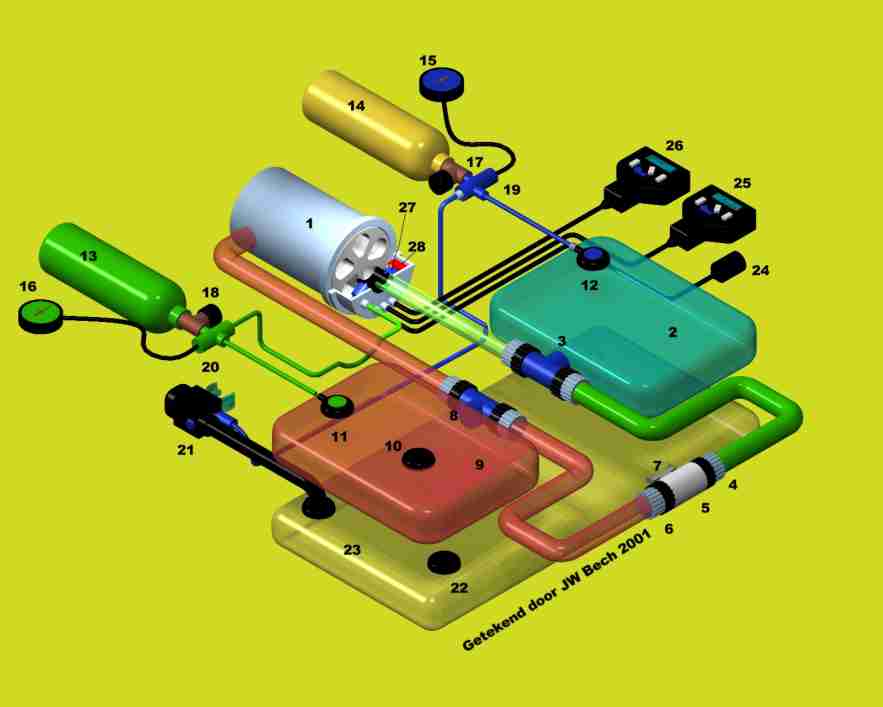

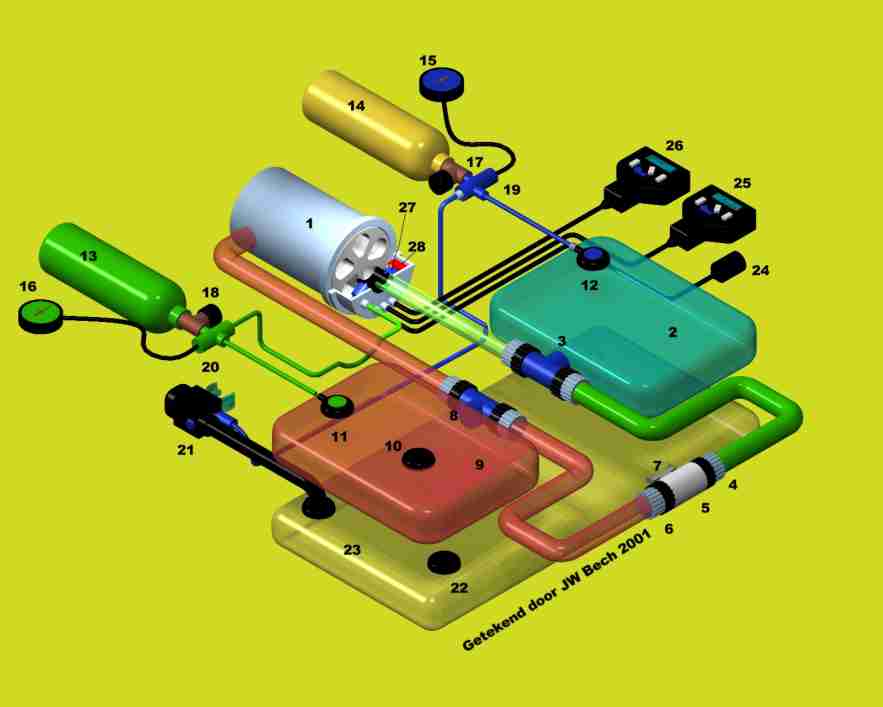

1.Scrubber

-

2.Counter lung (inhale)

-

3.Water trap

-

4.Inhale valve

-

5.Mouthpiece assembly (open/close)

-

6.Exhale valve

-

7.Mouthpiece

-

8.Water trap

-

9.Counter lung (exhale)

-

10.Over pressure valve

-

11.Oxygen inflator

-

12.Diluent inflator

-

13.Oxygen cylinder

-

14.Diluent cylinder

- 15.Diluent gauge

- 16.Oxygen gauge

- 17.Diluent valve

-

18.Oxygen valve

-

19.First stage for reducing HP diluent

-

20.First stage for reducing HP oxygen

-

21.Inflator / regulator

-

22. Over

pressure valve Wing

-

23.Wing

-

24.Buzzer

-

25.Master/Slave controller

-

26.Master/Slave controller

-

27.Oxygen cells

-

28.Solenoid

|

-

The breathing loop of the CCR and the breathing

loops of the SCR and the O2 rebreather all share the same

parts:

-

mouthpiece assembly, in- and exhale valves, hoses

for gas supply and gas removal and scrubber. Both at the inhale and at

the exhale side a counter lung is fitted. In the scrubber lid of the

closed circuit rebreather there are 3 oxygen cells placed, for measuring

the oxygen level after the CO2 has been removed from the gas.

The controller regulates the solenoid (looks like an electronic valve)

that injects oxygen until the set point is reached. The diver can adjust

the gas volume in the loop by manual* diluent injection. The volume in

the loop and the counter lungs decreases as soon as the diver descents

by the increasing water pressure. In some rebreathers this process can

be regulated by a computer (Cis Lunar MK5) or by adding an ADV

(Automatic Diluent addition Valve); on every depth the loop volume will

be sufficient and the set point can be maintained by keeping the oxygen

level regulated by the controller. During the dive the mouthpiece cannot

be taken out because the loop will be flooded by water and the system

will no longer be able to function properly. In case the mouthpiece is

dropped by accident, most off the water will be trapped by the water

traps near the counter lungs. The picture shows the Inspiration from

Ambient Pressure Diving. Other CCR rebreathers may show some differences

in operation or parts. Thatís why the CCR rebreather diver training is

apparatus specific.

*In the standard model of the Inspiration rebreather this needs to be

done manually. Most Inspiration divers install such a device themselves,

but an ADV can be fitted by the factory as an option. The ADV is in fact

a second stage placed on the inhale counter lung. In case of under

pressure in the loop the ADV will supply gas from the diluent cylinder,

so the diver can inhale with comfort. It will be clear that most of the

time this will happen during the descent because the gas volume

decreases when the pressure increases.

|

New developments:

|

|

Modern CC rebreathers offer real time

decompression. Real time decompression means that the system is

equipped with a computer that measures the oxygen content and

thus knows the nitrogen content to calculate decompression

obligations. Also Trimix version can be uses since the content

of the makeup gas (diluent) can be programmed into the computer.

Decompression is calculated with several algorithm like

Buhlmann, VPM or RGBM for example. Alarms can be programmed and

several user options are available. Real time decompression has

the big advantage that the rebreather controls the setpoint by

measuring the oxygen. It is the best way to calculate

decompression with the same oxygen cells.

|

|

|

Head up displays (HUD) are more and more

popular. Beware that a HUD is an additional device for the diver

to have visual control over the rebreather status. It is not a

primary source for knowing the pO2!

|

|

|

One of the major dangers of the rebreather is

the risk of Hyperoxia. Now in 2010 there is not a reliable CO2

detection system that offers the diver early information that

high CO2 levels are to be expected. The only reliable system on

the market today (may 2010) is the temp-stick technology. In the

scrubber there is a sensor with several heat detecting sensors

mounted linear in the heart of the scrubber. Software measures

the heat development of the chemical reaction and is able to

show and predict the remaining scrubbertime.

|

|

|

Rebreathers used in the EU should have CE

marking and be build conform EN 14143:2003. A new version will

be released the next few years.

|

|

|

CC rebreathers might be equipped with Bail Out

Valves (BOV). These BOV's offer the diver a fast way to switch

to open circuit.

|

|

|

The latest generation of CC rebreather also have

a "black box". This technology offers the diver a way to log his

dives, and the factory to read out data in case of an accident.

|

|

|

|

| |

|

|

|

|