|

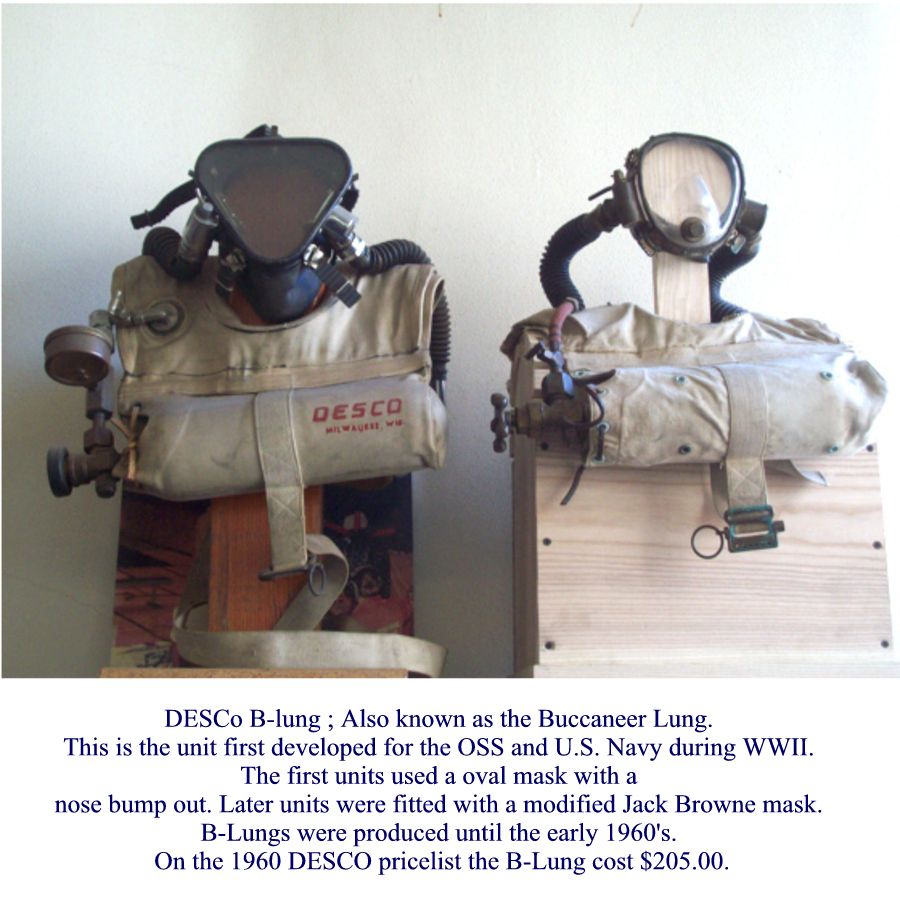

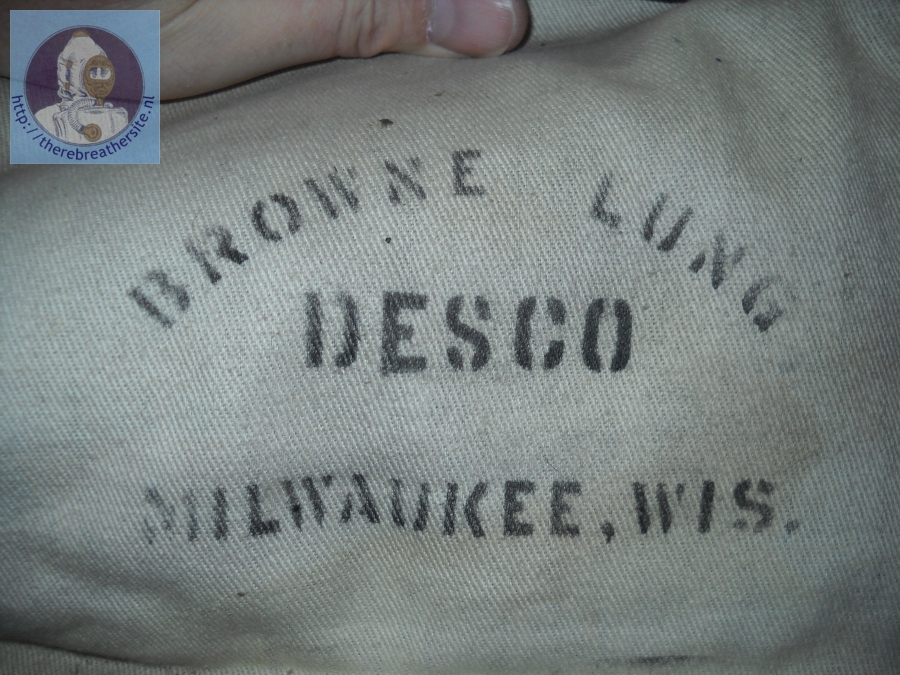

For many years I have tried to find a Desco

rebreather. These units are relative rare in Europe. Desco made

a A, B and C lung. I have been looking for a C-lung as my holy

grail, although Max Nohl his helmet would be even better ;). I

was fortunate to find a Buccaneer Lung or B-lung. This page

tells you about the history of this lung and his designer Jack

Browne. I have made a tear down of this wonderful American

oxygen rebreather. Please enjoy some diving history. The shown

B-lung was made in 1944 during World War II.

|

| |

|

|

History

of Jack Browne designer of the B-Lung

|

|

Jack Browne was

also a survivor of tin can diving as a boy. His father was an

executive with the Goodrich Transportation Company in Milwaukee.

Jack became interested in diving while a freshman in high

school. He would take on jobs for pay or just dive for fun.

He also had a knack for invention and his first diving helmet

was literally a tin can. In 1934 he was working with Max Nohl

diving on local wrecks.

A captioned photo appears in The Milwaukee Journal April 4, 1935

of Jack and his friends Paul Gallun, Fred Lange, and Bob Wescott

testing a home made

diving helmet in a Shorewood swimming pool.

When Max Nohl and John Craig began work on the equipment for the

Lusitania salvage Jack was ready to pitch in.

The custom diving dress they needed was stitched together from

canvas and taken to the N.L Kuehn Rubber Company to be made

watertight.

Norman Kuehn was to become a mentor to Jack and an angel to the

new company. The Nohl, Browne, Craig collaboration in 1937

resulted in the

forming of Diving Equipment and Salvage Company. Jack was to be

president of the new firm but there was a problem. As a

principal in the corporation

he needed to be 21 years old. DESCO would not be formally

incorporated until May of 1938 when Jack became “legal”.

Mr. Kuehn signed on as Vice President, and a local attorney Earl

Wanacek as secretary/treasurer.

DESCO was located in the Kuehn Rubber Co. facility on north 4th

street. Kuehn himself provided financial support and business

advice.

After the Lusitania project collapsed and Nohl and Craig had

moved on to other things Jack determined to keep DESCO alive.

Through 1938 to December of 1941 the small firm plodded along.

Jack experimented with new designs for breathing tanks and

lighter suits.

With the outbreak of World War Two Mr. Kuehn urged Jack to go to

Washington. “Tell the Navy what you know about diving suits.

Show the boys what you have done and can do.” Jack did. In

January of 1942 he headed east and returned with a $5000 order

for three self-contained suits.

That first order led to others until DESCO was producing more

diving equipment than anyone else in the world.

Jack and DESCO were major contributors to the Navy war effort.

DESCO/Navy collaborative efforts led to the development of the

Browne Mask,

Lightweight Diving Suit, and Buie Diving Helmet. Navy Doctor

Albert Behnke worked with Browne and Dr. End on refinements in

deep diving on Helium.

Emerson Buie came to DESCO with his idea for a low volume diving

helmet to deal with mine clearance in harbors.

The US Office of Strategic Services asked Jack and DESCO to

build them compact Oxygen rebreathers for covert operations.

Along with special development projects was the day to day

operation of a company supplying 80% of the country’s diving

equipment needs.

By 1945 DESCO had its own pressurized wet tank for research and

development. On April 27, 1945, Jack used this tank to "dive" to

still a new

record depth of 550 feet of seawater. As in the case of Nohl's

earlier dive, he breathed a heliox mixture under the supervision

of Dr. End.

Both dives were milestones in the development of modern

techniques of mixed-gas diving. Max Nohl was asked how he felt

about Jack breaking his record.

Max replied "records are made to be broken".

In 1946, Norman Kuehn and Jack Browne sold the company to the

general manager E.M Johnson and a group of investors.

Jack moved on to help run the family automobile dealership

Browne Motors Chrysler Plymouth on 20th Street & North Ave. in

Milwaukee.

In June 1949 he became president of the dealership after his

father George passed away.

Jack makes the local papers occasionally, most notably for a

bridge on the Fox River in Green Bay having to open so he could

land his seaplane.

He also made the paper with a story on the spider monkey he

keeps on his yacht.

Not much more was heard from him until 1958 when he is flying

guns to Fidel Castro's Cuban rebels.

He is forced down by the Batista Cuban Air Force and imprisoned.

Browne managed to escape from prison and steal back his plane.

On the flight to Florida he runs out of fuel over the Florida

Keys. He was rescued by the Coast Guard.

Jack retired to the Virgin Islands and passed away in 1998 from

a heart attack.

Source: with kind permission of the Desco

corporation.

|

| |

|

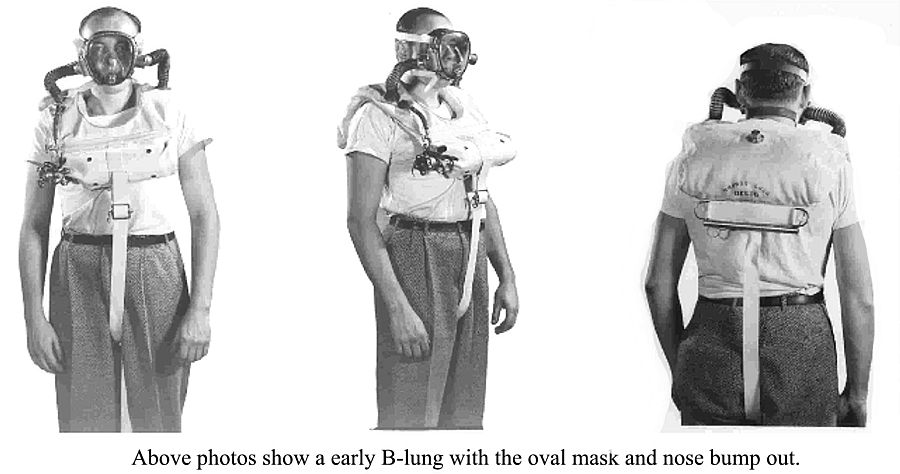

| Large number of

Desco Buccaneers are made for the US navy. (picture courtesy of

Desco corporation) |

| |

|

| |

|

| |

|

| |

|

|

|

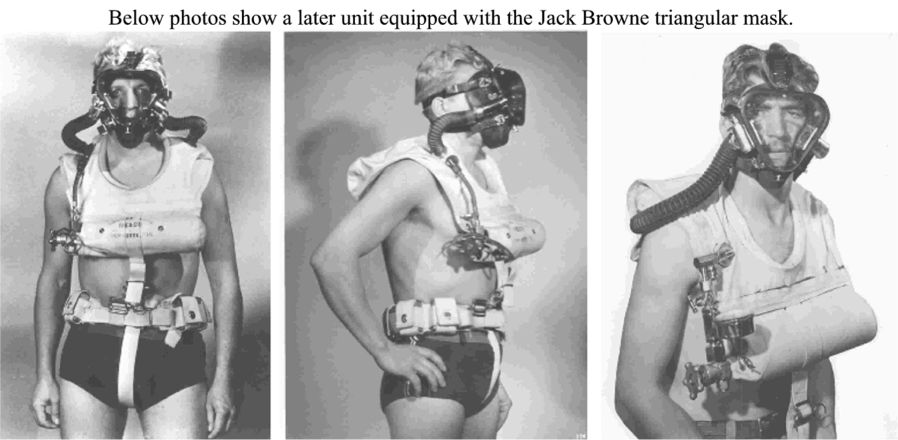

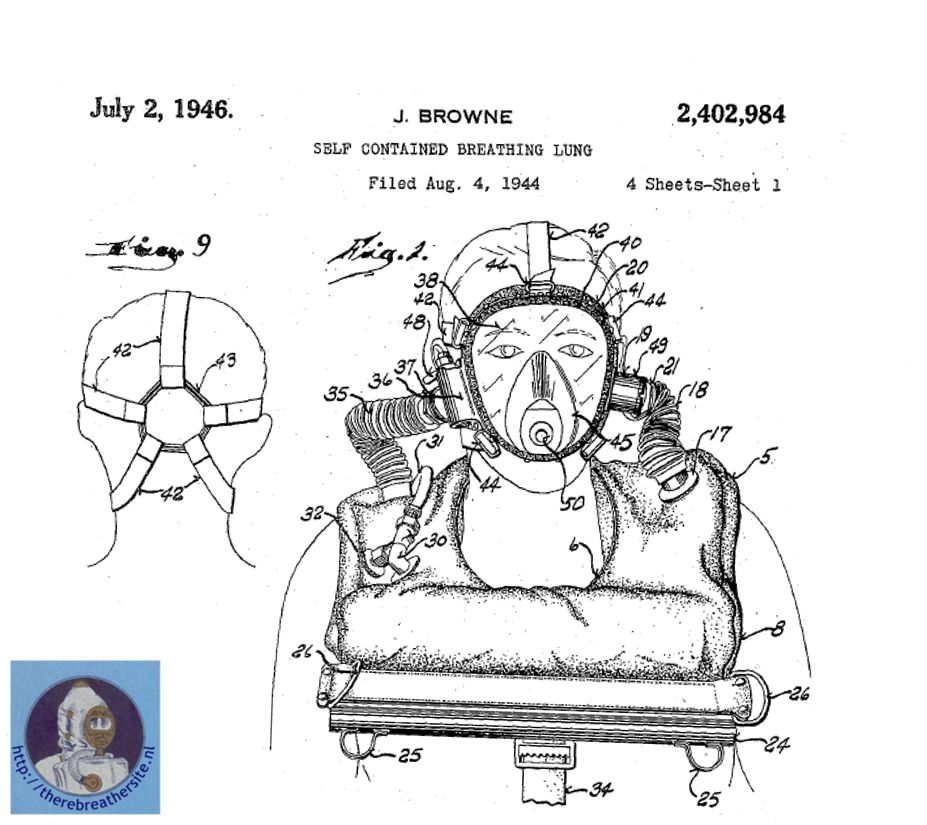

Patent |

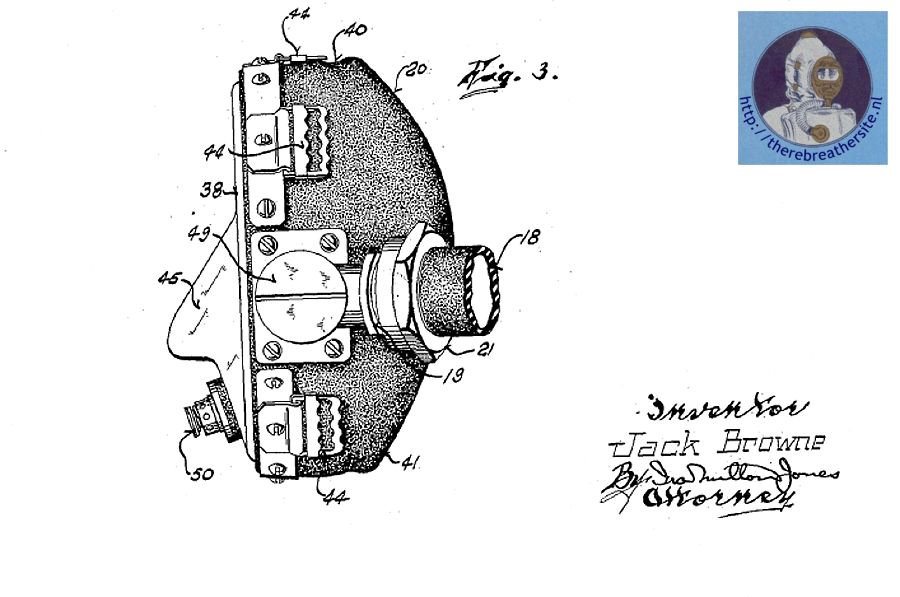

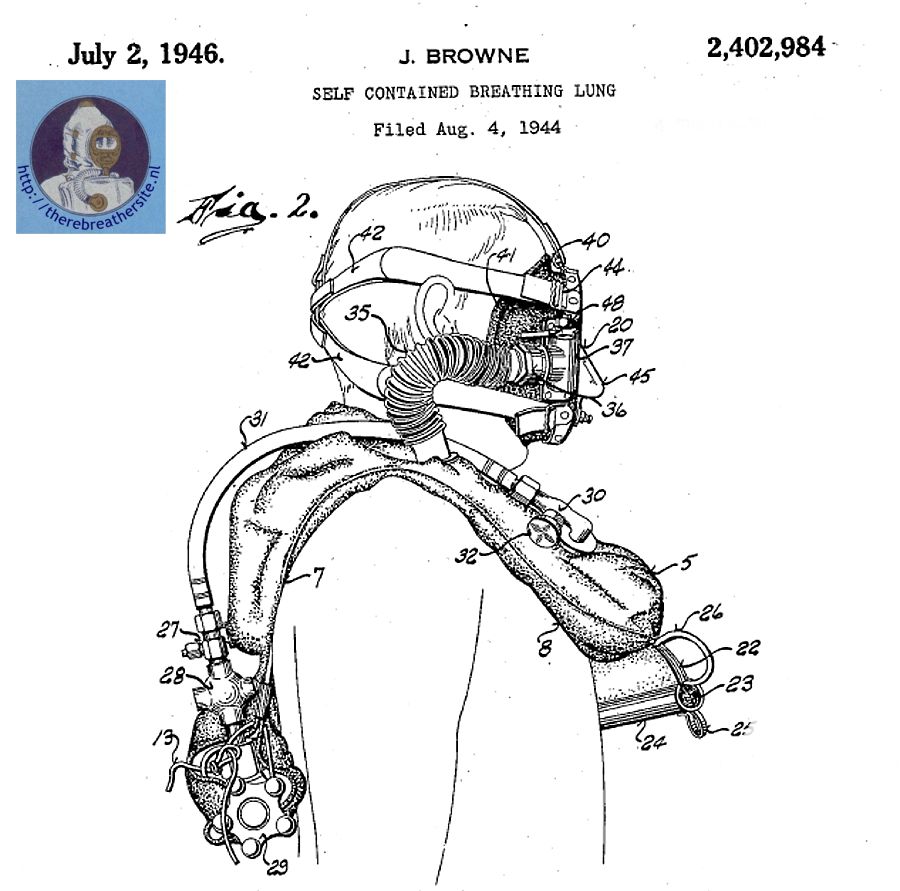

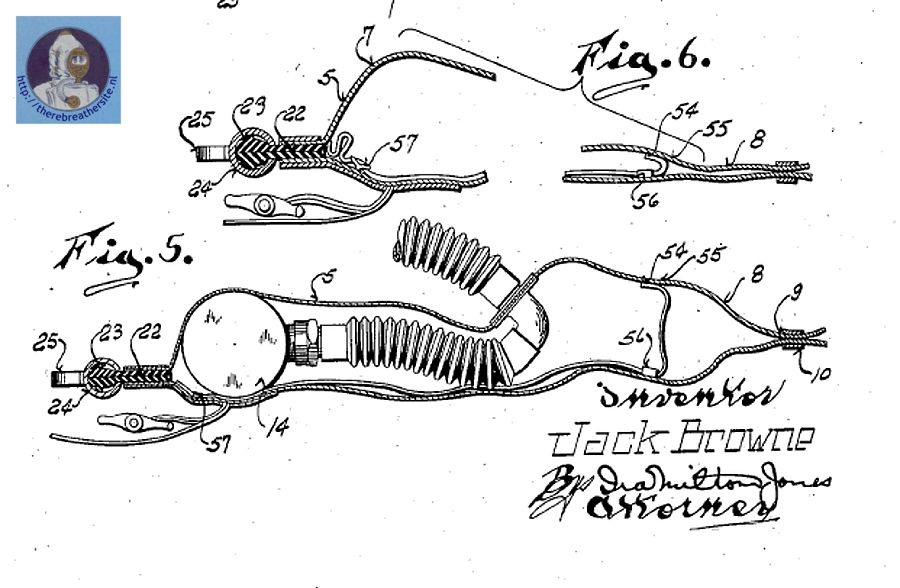

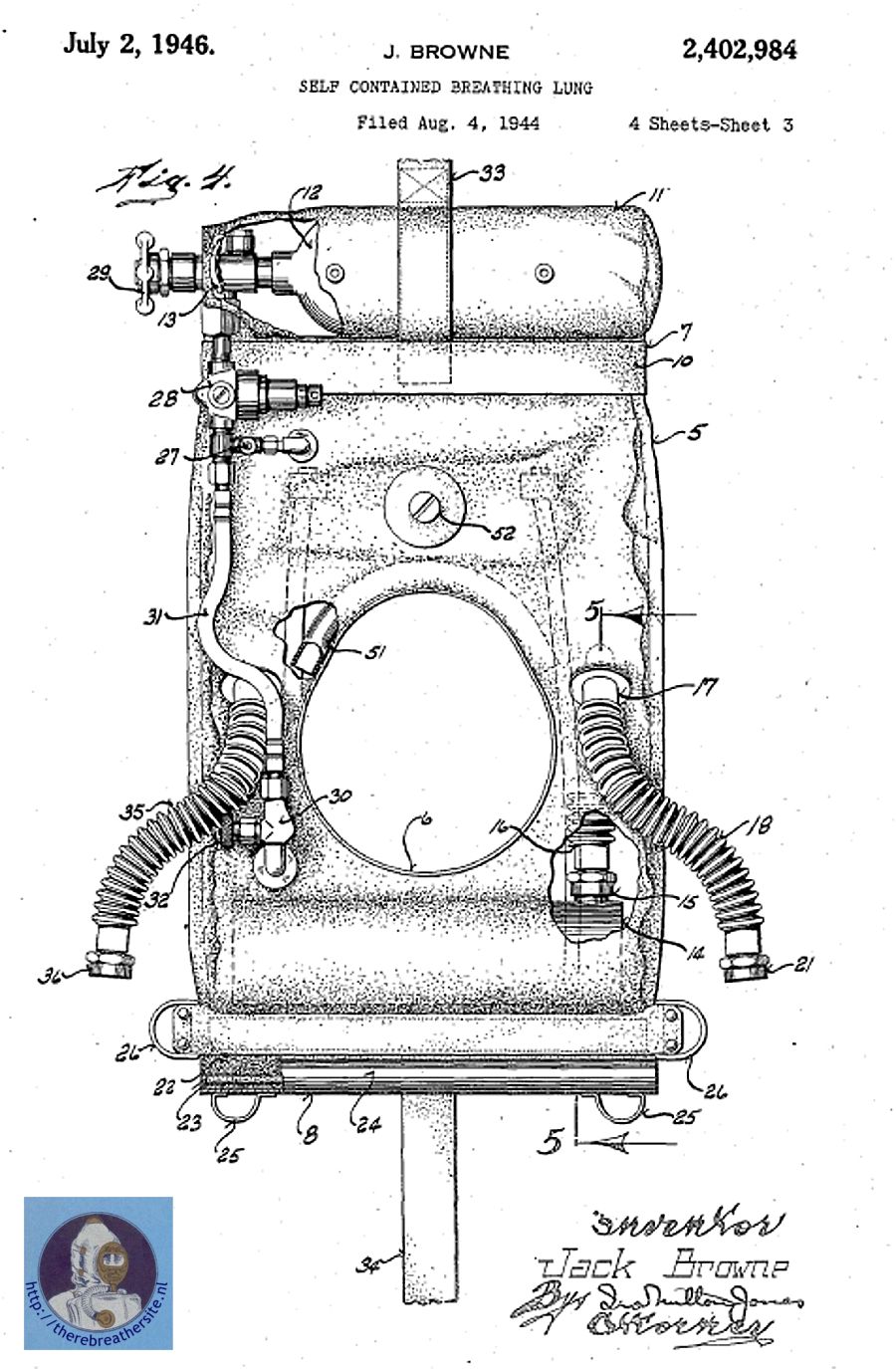

| When I

looked at the Browne patent, first thing that I noticed was the

unit was designed with the counterlung in front of the diver!

All photos show the unit with the counterlung on the back! This

is a very strange thing since there is also an extra valve

placed on the lungside as shown in the patent. It looks if the

unit was turned for the picture later. The following picture

shows the unit in use as described in the patent! |

|

| |

|

| |

|

| |

|

| Please notice the CL is in front

of the diver and the extra regulator valve on the lung |

| |

|

| |

|

| |

| |

| Overview |

|

| Finally my own desco oxygen

rebreather! |

| |

|

| The beautiful made weight belt

almost 70 years old!! |

| |

|

| |

| |

|

Clip for closing the

counterlung |

| |

|

| The brass clip closes the

counterlung by pressing the rubber parts together. The rubber

has been made smooth a lining of canvas like material |

| |

|

| |

|

| canvas |

| |

|

| A ring is attached to pull the

clip in opposite direction of the counterlung |

| |

|

| Full brass clamp |

| |

| |

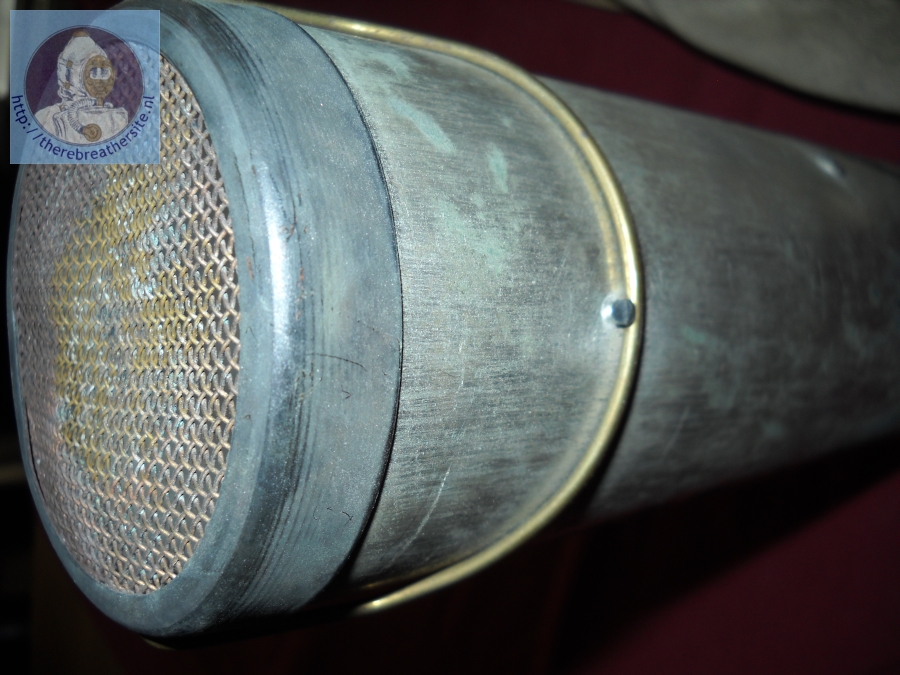

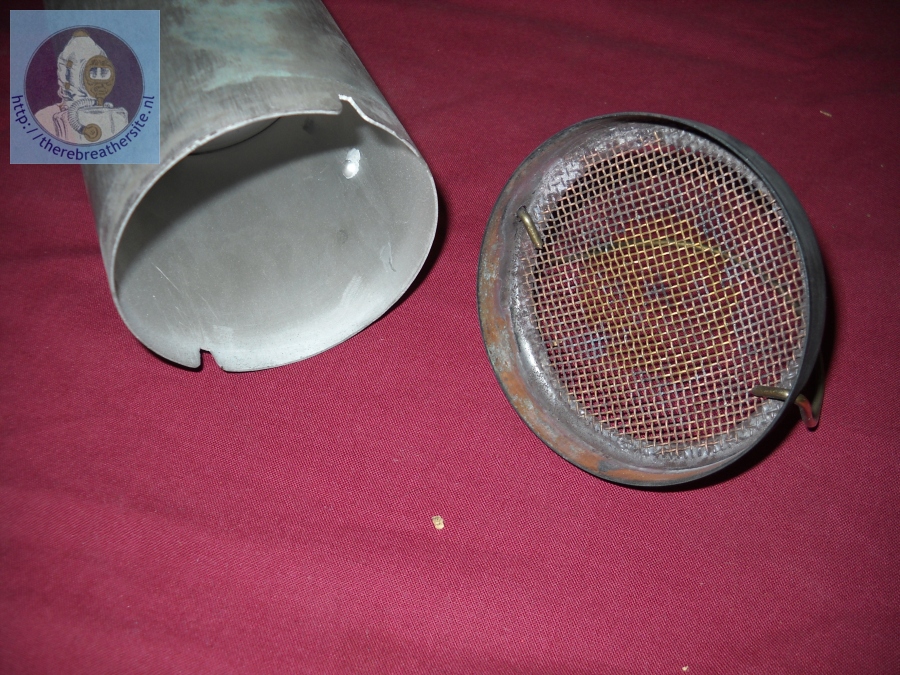

| Scrubber |

| |

|

| After the clip has been detached

the scubber can be taken out of the Counterlung. |

| |

|

| Inside the scrubber the

exhalehose is attached to the scrubber. This is the only hose

attached to the scrubber. |

| |

|

| A tinned(?) surface prevent the

brass from corrosion |

| |

|

| |

|

| |

|

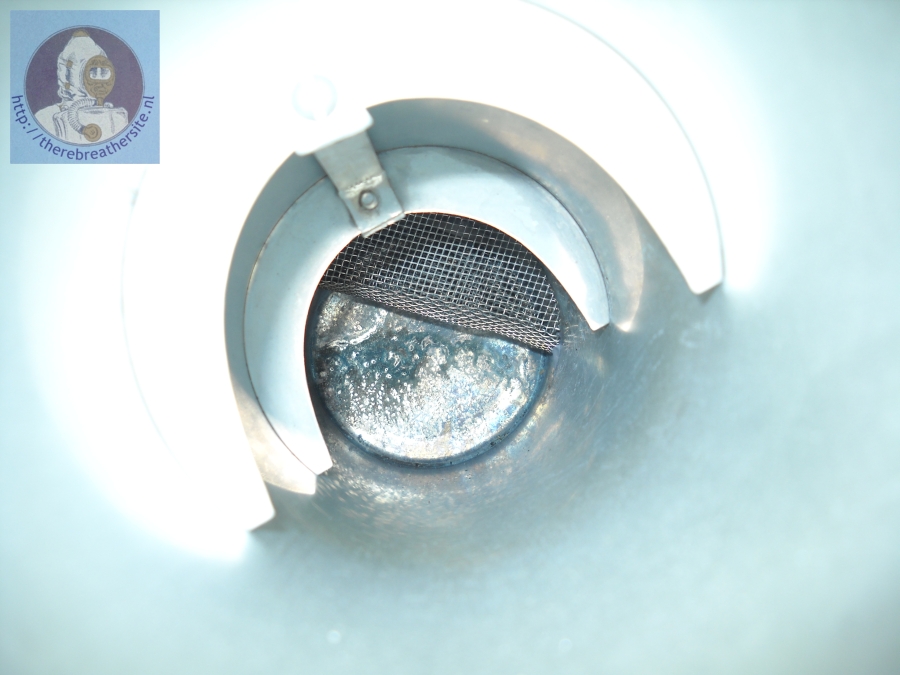

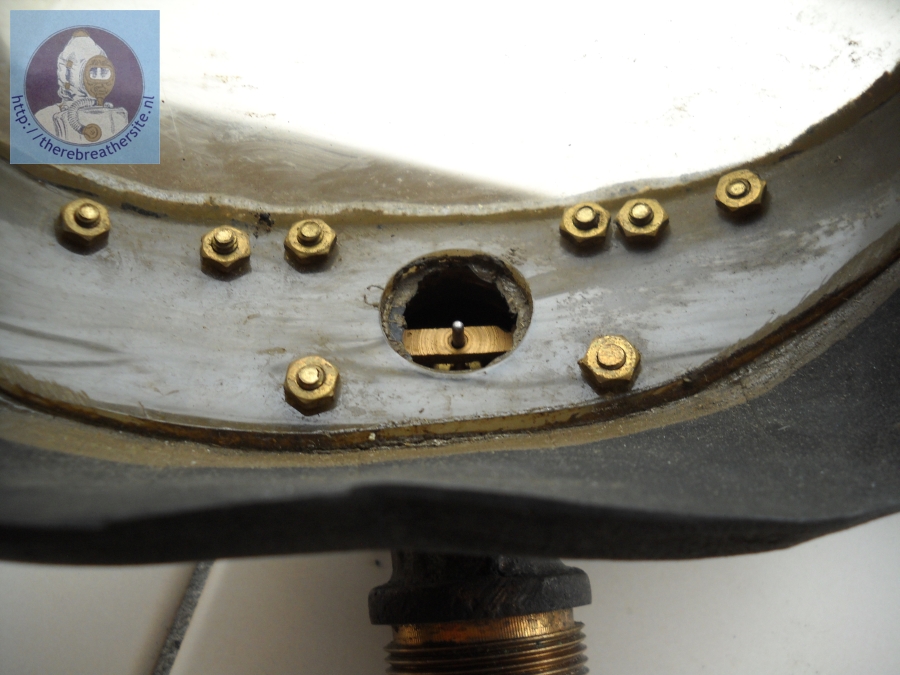

| One side of the scrubber has a

fine mesh that is in direct contact with the inside of the lung |

| |

|

| |

|

| Diameter 24 cm |

| |

|

| length ~28 cm. Resulting in a

1,3 ltr scrubber. To modern standard as a rule of thumb 1 kilo

equals 70 minutes so this scrubber could be working fine for 91

minutes. That equals the company's claim that the unit can be

used from 1 - 1,5 hour. Please do not copy this figures for your

design to built your own scrubber. The length to diameter and

WOB has to be tested and is very

critical! |

| |

|

| The closing mechanism is

wonderful simple and effective! |

| |

|

| |

|

| |

|

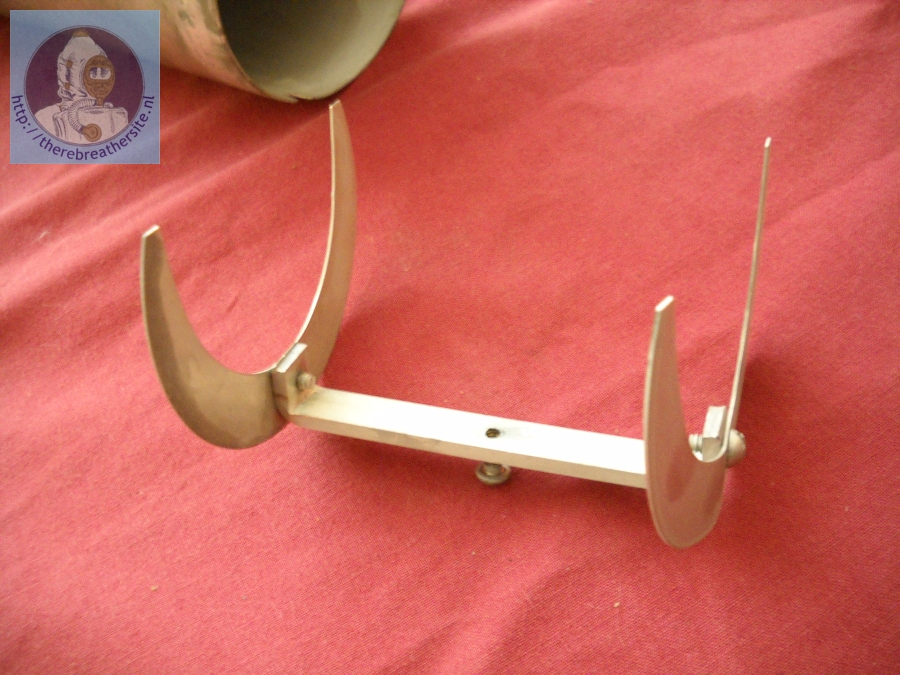

| Inside there are two plates

preventing channeling! |

| |

|

| The plates are fixed with one

brass screw. |

| |

|

| |

|

| |

|

| lets put the scrubber back in

the lung |

| |

|

| |

|

| |

| |

|

Over pressure

valve of the Counterlung |

| |

|

| The valve is located in the

middle of the counterlung |

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| The rubber has been hardened and

the valve must be restored to work properly. |

| |

| |

|

Breathing hoses |

| Early

rebreather all have small diameter valves and hoses. This unit

is no exception. Although the unit was used to 33 ft (10mtr) the

work of breathing must have been relative high. Today diving to

10 mtrs on pure oxygen is not common and called very dangerous

due to the partial pressure of oxygen of 2.0 bar! |

| |

| |

|

| |

|

| |

|

| |

| |

| Mask |

| |

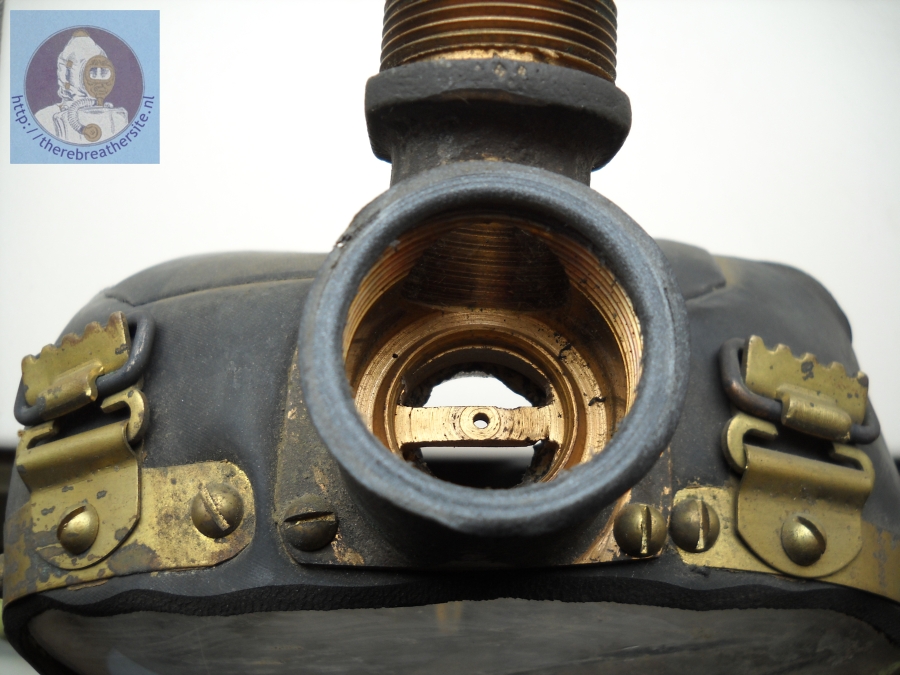

| The mask of the B-lung is a

piece of art. It has brass parts made with craftmanship and

machines to very high quality parts. Valves are made extremely

simple so every diver was able to maintain the mask themselves! |

| |

|

| |

|

| |

|

| |

|

| head straps of rubber and canvas |

| |

|

| glued |

| |

|

| |

|

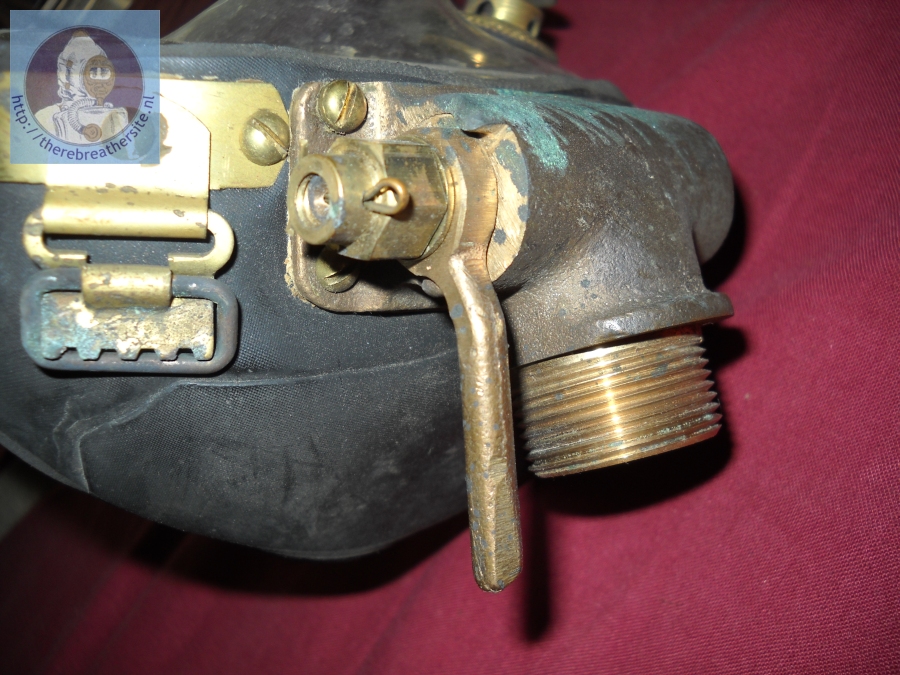

| inhalation valve and surface

shut-off valve. The diver could shutdown the rebreathercyle by

closing this inhalation valve and breath by using the purge

valve in front of his mask. The factory also recommended to keep

some water in the mask to clean fog inside the mask! |

| |

|

| the narrow valve opening |

| |

|

| in closed position, diver on the

surface |

| |

|

| |

|

| this is the inhale valve! A very

simple and effective design. (although dangerous, when leaking

CO2 could be rebreathed...) |

| |

|

| |

|

| |

|

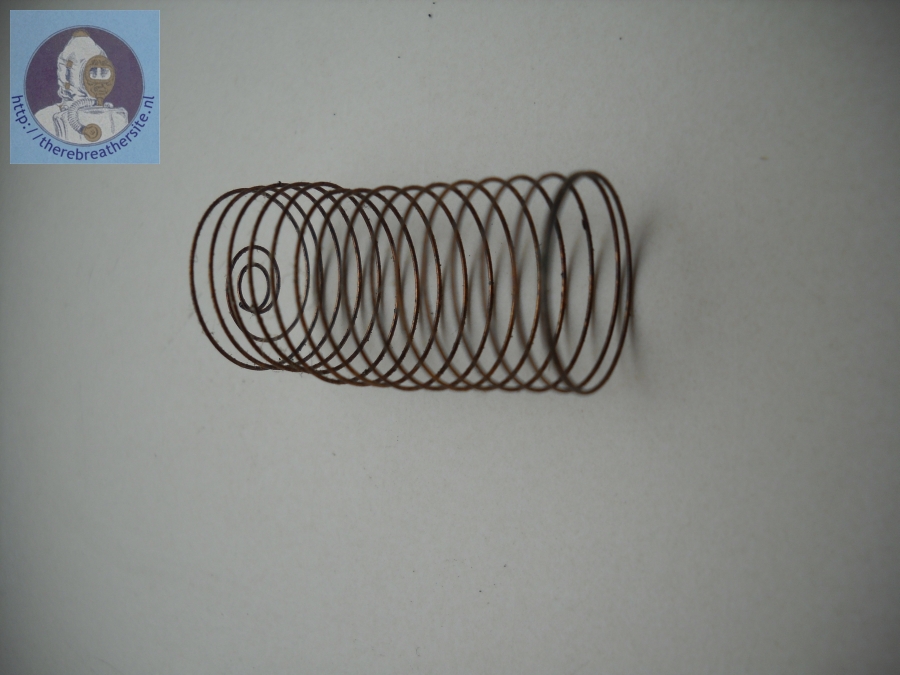

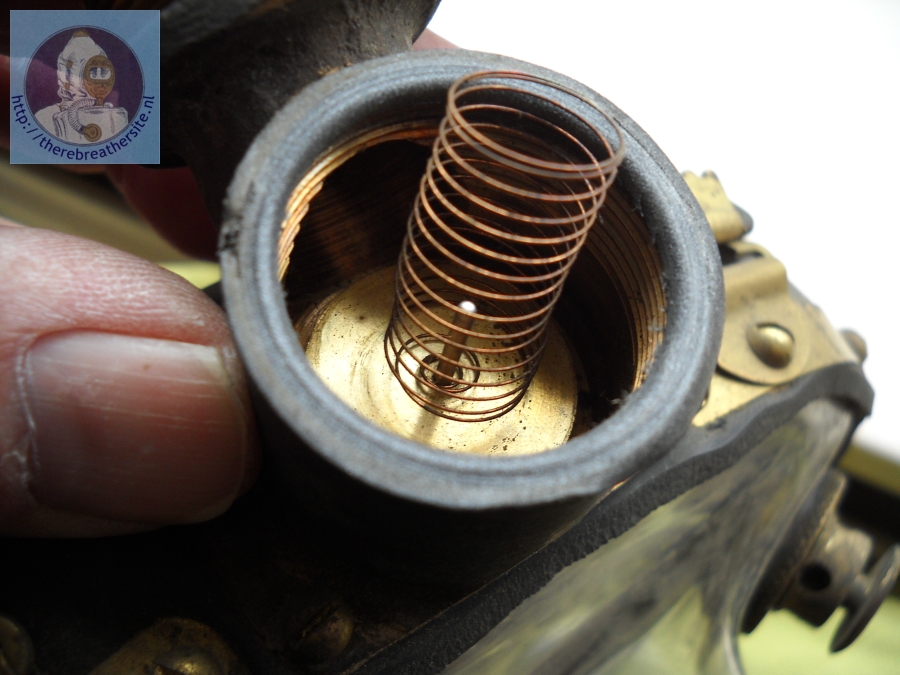

| This is the spring operated

exhale valve |

| |

|

| A valve with rubber seat is

fitted and operated by exhaling against the springpressure |

| |

|

| exhale valve |

| |

|

| exhale spring made of red copper

or brass |

| |

|

| valve itself |

| |

|

| |

|

| on this pin the spring is

attached and closed in the chamber |

| |

|

| |

|

| |

|

| |

|

| complete exhale valve |

| |

| |

| Oxygen

bottle |

| |

|

| The bottle is aatached with

leader rope |

| |

|

| |

|

| |

|

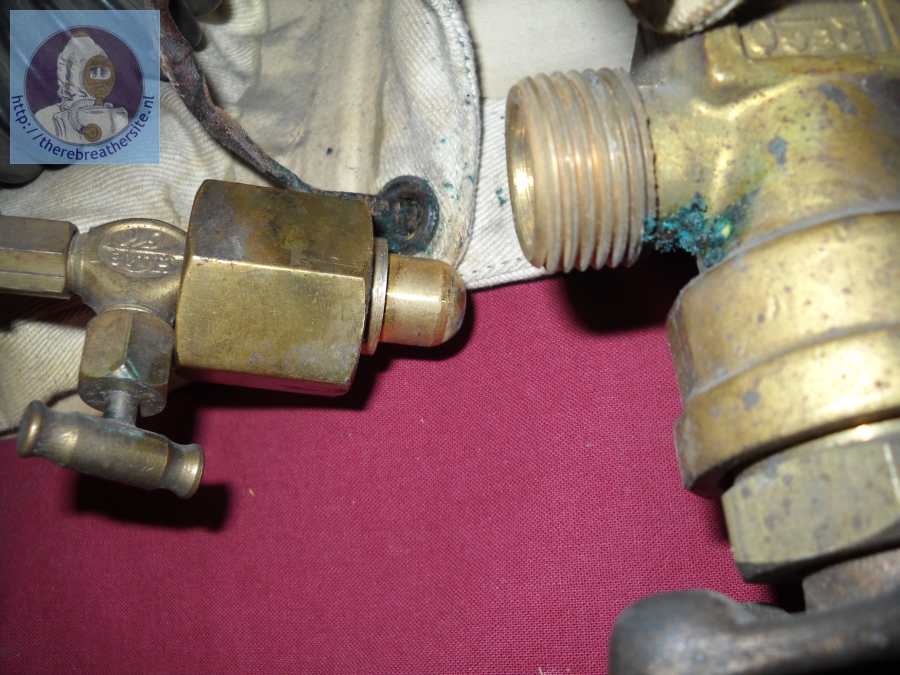

| the 125 bar connector |

| |

|

| Original 1944 RegO oxygen valve

and Desco bottle |

| |

|

| |

|

| |

|

| februari 1944 marking! |

| |

|

| DESCO inscription |

| |

|

| |

| |

|

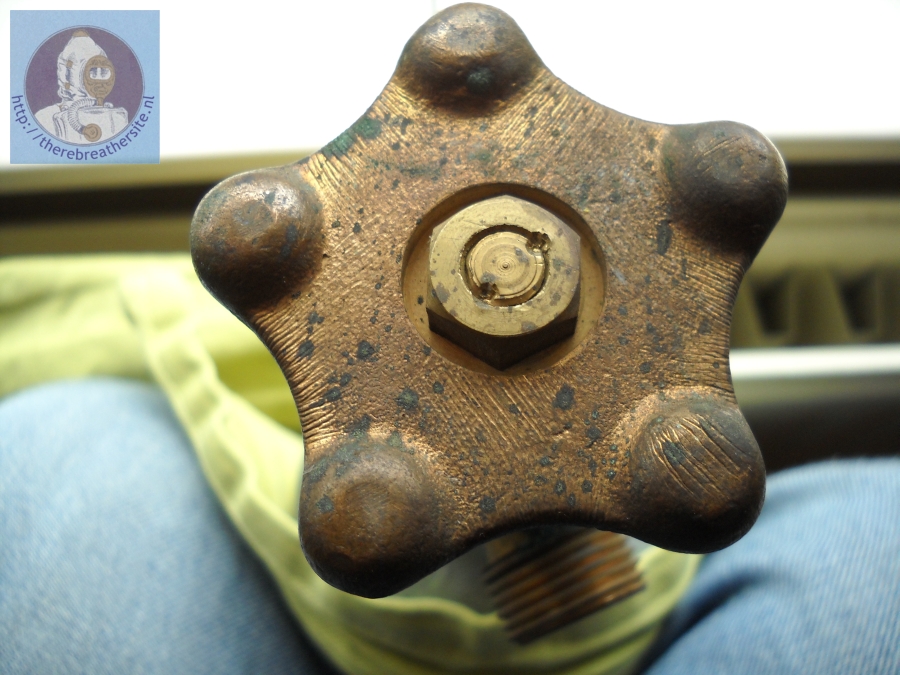

Metering valve |

| |

|

| |

|

| |

|

| |

|

| |

|

| The metering needle valve. |

| |

| |

| Weight

belt |

| |

|

| |

|

| |

|

| |

|

| the emergency pull-pin was a way

to dump the weight belt |

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

| |

| |

| So, that was all folks! If you

have any information about the B-lung or other Desco

rebreathers, please send it to jw.bech@quicknet.nl |

| |

| |

| |

| |

|

|

|

17-02-2013 |

|

Jan –

My history person has come through!

He says:

That is an old 300 series valve 1/4" MNPT on both ends, on the

hose side it had an adaptor to accept the hose assembly as a

push on, this was actually a bomber high altitude oxygen vest.

The 300 series valves were manufactured by Hoke in Queens, NY by

the Joseph Hoke Valve Company between the years of 1943

to 1949-1950.

There should be some other data on the opposite face of the

valve as well.

I hope this helps.

If you have further questions, please let me know.

Regards,

Sherri

Technical

Support Engineer

CIRCOR

Flow Technologies

Hoke Products

405 Centura Court

Spartanburg, SC 29303

Direct: 864/595-5166

Fax: 864/587-5608

sherri.rice@circor.com

www.hoke.com

|

| |

|

|

|

added 19-03-2013 |